| Grit: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Availability: | |||||||||

| Quantity: | |||||||||

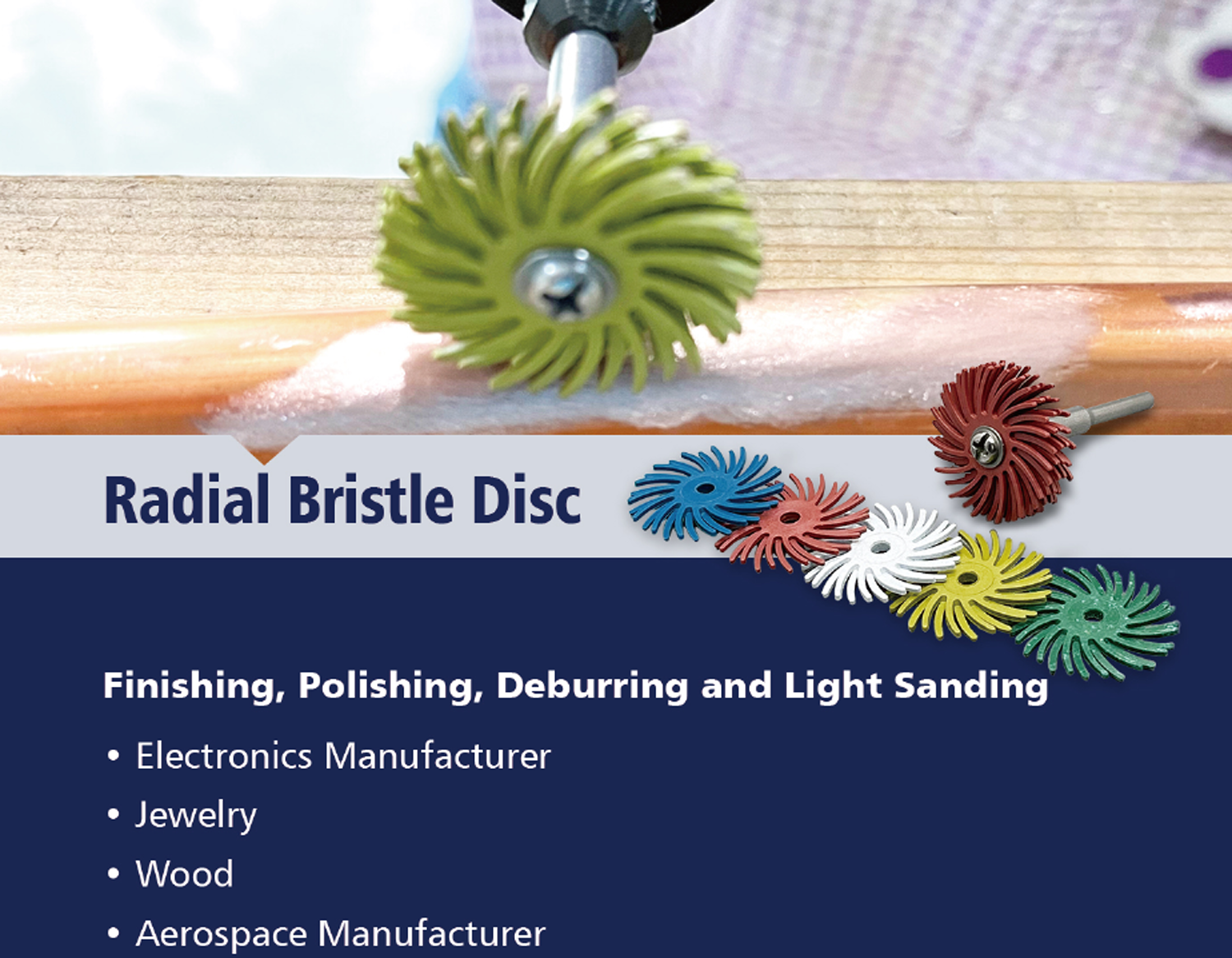

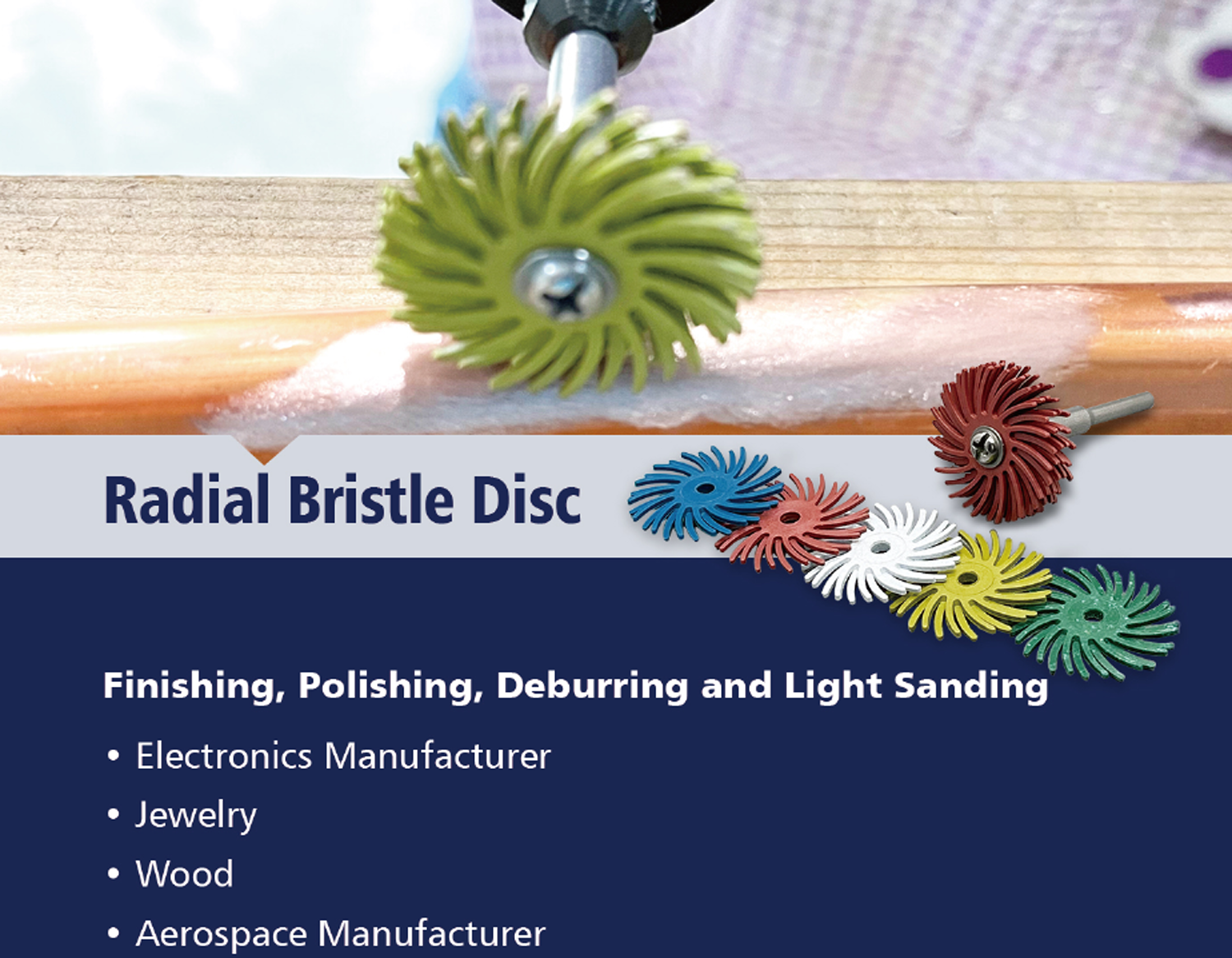

| The radial bristle disc is suitable for a variety of metal materials, providing more contact surface for effective stripping, deburring, blending, finishing, polishing, cleaning and coating removal. Keep the radial bristle disc in a safe position, only It only takes light pressure to get the desired surface treatment effect.The radial bristle disc stands as a cost-effective, high-performance alternative to established international brands like 3M and Norton Abrasives. | |||||||||

3/4"Radial Bristle Brushes & Discs

Nice Top

A radial bristle disc is a type of abrasive tool used for surface conditioning, deburring, and polishing. It consists of multiple flexible bristles arranged in a radial pattern on a disc-shaped base. These bristles are typically made of a durable material such as nylon or abrasive-infused rubber.

The radial arrangement of the bristles allows for efficient and uniform surface treatment. As the disc rotates, the bristles flex and conform to the contours of the workpiece, providing consistent contact and effective material removal.

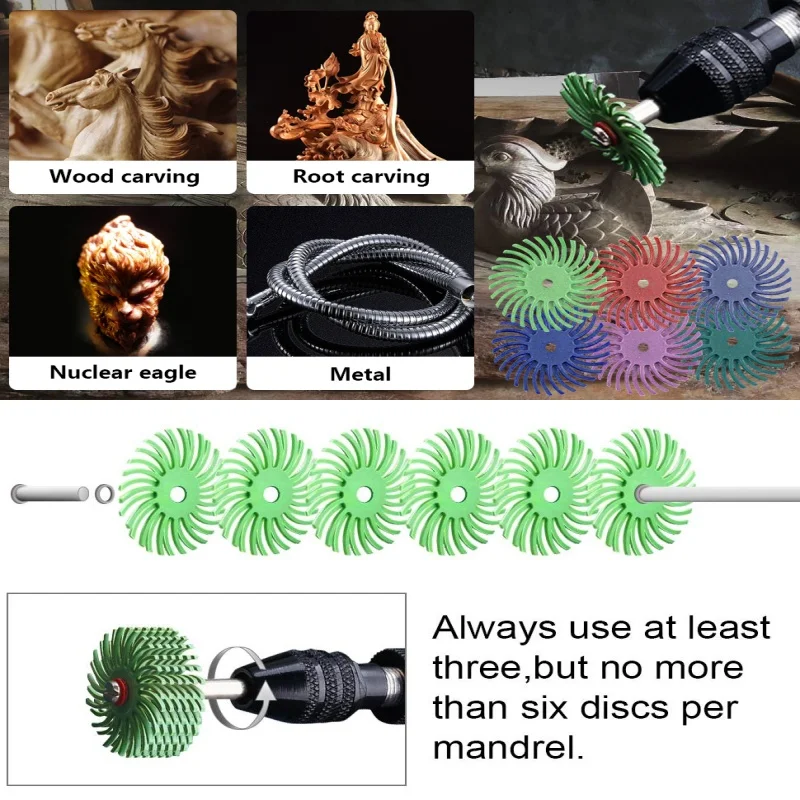

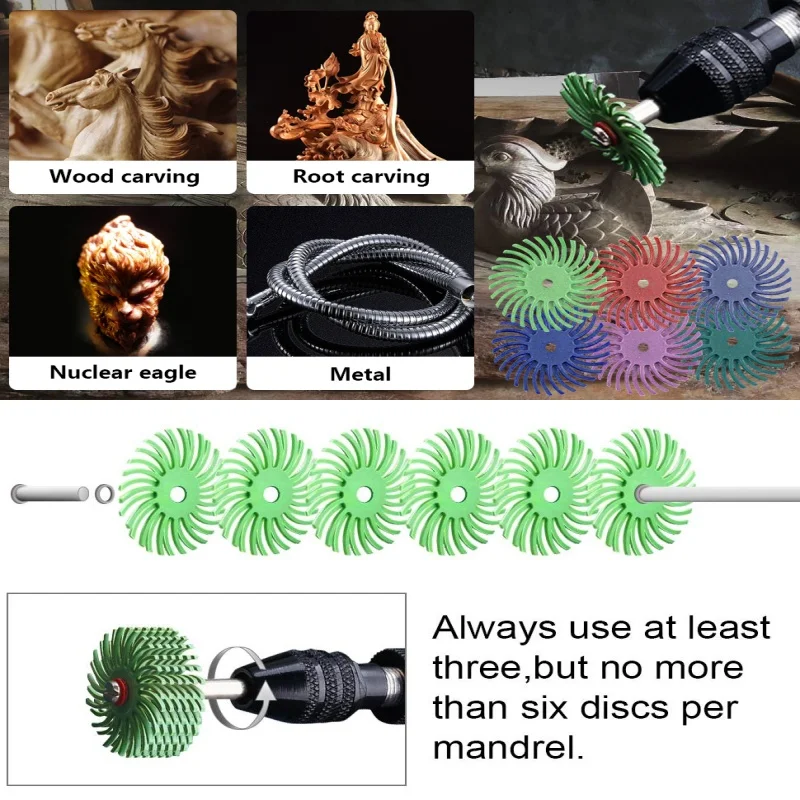

Radial bristle discs are available in various sizes, typically ranging from 1 inch to 8 inches in diameter. They are commonly used with rotary tools such as angle grinders, die grinders, or bench grinders. The discs can be easily attached to the tool's spindle or mandrel.

Product Parameters

| Abrasive Material | Precision Shaped Ceramic Grain |

| Application | Strip, Deburr, Blend, Finish, Polish, Clean, Remove Coatings |

| Grit | 50#,80#,120#,220#,320#,400#,600#,1000#,2500#,5000# |

| Brands | Nice Top |

| Diameter | 3/4inch |

| Package Contents | 200pcs/set |

| Industries | Aerospace,General Industrial,Metalworking,Woodworking,Jewelry processing |

| For Use With | Common electric,Pneumatic tools,Rotary tool,Angle Grinder,Die Grinder,Drill |

| For Use On | Aluminum, Brass, Bronze, Carbon steel, Cast iron, Stainless steel, and other metals |

Radial bristle discs can be used on a wide range of materials, including metals, wood, plastics, and composite surfaces. They are suitable for both flat and curved surfaces, adapting easily to different shapes and contours. This versatility makes them ideal for various applications, from heavy-duty cleaning to delicate surface finishing, allowing operators to use a single tool across multiple tasks without compromising quality.

The flexible bristles allow for precise and controlled material removal, making radial bristle discs particularly suitable for delicate or intricate workpieces. This feature ensures that edges, corners, and complex geometries are treated evenly without overcutting or damaging the base material. As a result, operators can achieve professional-quality results even on parts that require a gentle touch.

Thanks to the radial arrangement of the bristles, these discs provide a uniform finish across the entire workpiece. The design minimizes the risk of uneven surfaces, streaking, or patchy results, ensuring a high-quality, visually appealing finish every time. This consistency is critical in industries where surface appearance and precision are essential, such as automotive, aerospace, and electronics manufacturing.

Radial bristle discs are designed for durability and extended service life. The high-quality bristles resist wear and tear even under continuous operation, maintaining consistent performance over long periods. This longevity reduces the frequency of replacements, saving both time and cost while ensuring reliable results throughout the disc’s usable life.

These discs are simple to install and remove from rotary tools, enabling quick changes during ongoing projects. Their user-friendly design allows operators to switch between different grit sizes or disc types efficiently, minimizing downtime and improving workflow. This convenience is especially valuable in production environments or workshops handling multiple tasks simultaneously.

Radial bristle discs are inherently wear-resistant and maintain stable performance throughout extended use. Even during prolonged operation, they generate minimal heat, preventing damage to both the workpiece and the operator. Their consistent, safe performance makes them a dependable choice for a wide range of industrial and precision applications, ensuring efficiency and peace of mind for the user.

Applications

Metalworking & Fabrication

Ideal for deburring, cleaning, and finishing metal parts such as weld joints, machined edges, and sheet metal components. The flexible bristles conform to contours and complex shapes, ensuring precise and uniform surface conditioning without damaging the base material.

Automotive Manufacturing

Commonly used for removing paint, rust, oxidation, and gasket residue from engine parts, wheels, and frames. It provides consistent surface preparation for coating, welding, or bonding, while maintaining critical tolerances and part geometry.

Aerospace Industry

Perfect for precision cleaning and finishing of turbine blades, engine housings, and structural components. The disc’s controlled abrasion helps achieve fine surface finishes required in high-performance, safety-critical applications.

Jewelry & Electronics

Used for polishing delicate surfaces, removing oxides, and cleaning solder joints without scratching or distorting fine details. The radial bristle disc offers gentle yet efficient action—ideal for precious metals, circuit boards, and micro-components.

Medical Equipment Manufacturing

Ensures burr-free, contamination-free finishes on stainless steel, titanium, and surgical-grade alloys. Widely applied in the production of surgical instruments, implants, and precision tools that demand high surface integrity and hygiene.

Woodworking & Plastic Processing

Suitable for surface cleaning, texturing, and finishing of wood, plastics, and composites. The disc prevents smearing or melting, providing a clean, smooth finish ideal for decorative pieces, furniture, or molded components.

Frequently Asked Questions (FAQ)

Q1: why should you buy from us not from other suppliers?

A: Nice Top has strong capability to design and produce world top convolute wheel, unitized wheel,bristle brushes & discs,non woven Polishing wheel,laser braze finishing wheel etc. We give you competitive price and never comprise to quality.

Q2: Can it be used on both manual tools and automated systems?

A: Yes, it is compatible with handheld grinders as well as robotic finishing systems commonly used in automotive assembly lines.

Q3: Is it suitable for aluminum and stainless steel?

A: Absolutely. The wheel works effectively on aluminum alloys, stainless steel, silicon bronze, and other metals commonly used in laser brazing.

Q4: How long does one wheel last?

A: Service life depends on application conditions, but thanks to the cotton-fiber construction and premium abrasives, it lasts significantly longer than conventional finishing wheels.

Q5: Can you provide product samples before bulk orders?

A: Yes, we can supply samples for testing to ensure the wheel meets your application requirements.

Notice

The safety performance of Nice Top grinding wheel is strictly tested and has clear safety operation instructions. However, it is still essential to install and use it properly and stick to the safety instruction. Each product is labeled with the MOS: Maximum Operating Speed. The actual operating speed can not exceed the maximum operating speed.

Moreover, Please also pay attention to the mechanical protection, wear the mask, safety glass and safety shoe. Pay attention to the ventilation of the workshop.

When operating convolute wheel, we should pay special attention to the arrowhead marked on the product, and the direction of the arrow is the rotation direction of the product. The product must be operated with the right direction.

Whether you're in high-volume manufacturing or custom fabrication, our Convolute Wheels help you improve efficiency, surface quality, and process consistency. They're trusted by professionals across industries to deliver the perfect balance of performance, precision, and longevity.

Contact us today to discuss your specific needs, request samples, or get a tailored quotation—we’re here to support your finishing success.

A radial bristle disc is a type of abrasive tool used for surface conditioning, deburring, and polishing. It consists of multiple flexible bristles arranged in a radial pattern on a disc-shaped base. These bristles are typically made of a durable material such as nylon or abrasive-infused rubber.

The radial arrangement of the bristles allows for efficient and uniform surface treatment. As the disc rotates, the bristles flex and conform to the contours of the workpiece, providing consistent contact and effective material removal.

Radial bristle discs are available in various sizes, typically ranging from 1 inch to 8 inches in diameter. They are commonly used with rotary tools such as angle grinders, die grinders, or bench grinders. The discs can be easily attached to the tool's spindle or mandrel.

Product Parameters

| Abrasive Material | Precision Shaped Ceramic Grain |

| Application | Strip, Deburr, Blend, Finish, Polish, Clean, Remove Coatings |

| Grit | 50#,80#,120#,220#,320#,400#,600#,1000#,2500#,5000# |

| Brands | Nice Top |

| Diameter | 3/4inch |

| Package Contents | 200pcs/set |

| Industries | Aerospace,General Industrial,Metalworking,Woodworking,Jewelry processing |

| For Use With | Common electric,Pneumatic tools,Rotary tool,Angle Grinder,Die Grinder,Drill |

| For Use On | Aluminum, Brass, Bronze, Carbon steel, Cast iron, Stainless steel, and other metals |

Radial bristle discs can be used on a wide range of materials, including metals, wood, plastics, and composite surfaces. They are suitable for both flat and curved surfaces, adapting easily to different shapes and contours. This versatility makes them ideal for various applications, from heavy-duty cleaning to delicate surface finishing, allowing operators to use a single tool across multiple tasks without compromising quality.

The flexible bristles allow for precise and controlled material removal, making radial bristle discs particularly suitable for delicate or intricate workpieces. This feature ensures that edges, corners, and complex geometries are treated evenly without overcutting or damaging the base material. As a result, operators can achieve professional-quality results even on parts that require a gentle touch.

Thanks to the radial arrangement of the bristles, these discs provide a uniform finish across the entire workpiece. The design minimizes the risk of uneven surfaces, streaking, or patchy results, ensuring a high-quality, visually appealing finish every time. This consistency is critical in industries where surface appearance and precision are essential, such as automotive, aerospace, and electronics manufacturing.

Radial bristle discs are designed for durability and extended service life. The high-quality bristles resist wear and tear even under continuous operation, maintaining consistent performance over long periods. This longevity reduces the frequency of replacements, saving both time and cost while ensuring reliable results throughout the disc’s usable life.

These discs are simple to install and remove from rotary tools, enabling quick changes during ongoing projects. Their user-friendly design allows operators to switch between different grit sizes or disc types efficiently, minimizing downtime and improving workflow. This convenience is especially valuable in production environments or workshops handling multiple tasks simultaneously.

Radial bristle discs are inherently wear-resistant and maintain stable performance throughout extended use. Even during prolonged operation, they generate minimal heat, preventing damage to both the workpiece and the operator. Their consistent, safe performance makes them a dependable choice for a wide range of industrial and precision applications, ensuring efficiency and peace of mind for the user.

Applications

Metalworking & Fabrication

Ideal for deburring, cleaning, and finishing metal parts such as weld joints, machined edges, and sheet metal components. The flexible bristles conform to contours and complex shapes, ensuring precise and uniform surface conditioning without damaging the base material.

Automotive Manufacturing

Commonly used for removing paint, rust, oxidation, and gasket residue from engine parts, wheels, and frames. It provides consistent surface preparation for coating, welding, or bonding, while maintaining critical tolerances and part geometry.

Aerospace Industry

Perfect for precision cleaning and finishing of turbine blades, engine housings, and structural components. The disc’s controlled abrasion helps achieve fine surface finishes required in high-performance, safety-critical applications.

Jewelry & Electronics

Used for polishing delicate surfaces, removing oxides, and cleaning solder joints without scratching or distorting fine details. The radial bristle disc offers gentle yet efficient action—ideal for precious metals, circuit boards, and micro-components.

Medical Equipment Manufacturing

Ensures burr-free, contamination-free finishes on stainless steel, titanium, and surgical-grade alloys. Widely applied in the production of surgical instruments, implants, and precision tools that demand high surface integrity and hygiene.

Woodworking & Plastic Processing

Suitable for surface cleaning, texturing, and finishing of wood, plastics, and composites. The disc prevents smearing or melting, providing a clean, smooth finish ideal for decorative pieces, furniture, or molded components.

Frequently Asked Questions (FAQ)

Q1: why should you buy from us not from other suppliers?

A: Nice Top has strong capability to design and produce world top convolute wheel, unitized wheel,bristle brushes & discs,non woven Polishing wheel,laser braze finishing wheel etc. We give you competitive price and never comprise to quality.

Q2: Can it be used on both manual tools and automated systems?

A: Yes, it is compatible with handheld grinders as well as robotic finishing systems commonly used in automotive assembly lines.

Q3: Is it suitable for aluminum and stainless steel?

A: Absolutely. The wheel works effectively on aluminum alloys, stainless steel, silicon bronze, and other metals commonly used in laser brazing.

Q4: How long does one wheel last?

A: Service life depends on application conditions, but thanks to the cotton-fiber construction and premium abrasives, it lasts significantly longer than conventional finishing wheels.

Q5: Can you provide product samples before bulk orders?

A: Yes, we can supply samples for testing to ensure the wheel meets your application requirements.

Notice

The safety performance of Nice Top grinding wheel is strictly tested and has clear safety operation instructions. However, it is still essential to install and use it properly and stick to the safety instruction. Each product is labeled with the MOS: Maximum Operating Speed. The actual operating speed can not exceed the maximum operating speed.

Moreover, Please also pay attention to the mechanical protection, wear the mask, safety glass and safety shoe. Pay attention to the ventilation of the workshop.

When operating convolute wheel, we should pay special attention to the arrowhead marked on the product, and the direction of the arrow is the rotation direction of the product. The product must be operated with the right direction.

Whether you're in high-volume manufacturing or custom fabrication, our Convolute Wheels help you improve efficiency, surface quality, and process consistency. They're trusted by professionals across industries to deliver the perfect balance of performance, precision, and longevity.

Contact us today to discuss your specific needs, request samples, or get a tailored quotation—we’re here to support your finishing success.