| Availability: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Quantity: | |||||||||

| Trizact Cloth Belt utilizing unique grinding technology, the use of fine aluminum oxide particles provides a more refined and consistent grinding effect.The Trizact Cloth Belt stands as a cost-effective, high-performance alternative to established international brands like 3M and Norton Abrasives. | |||||||||

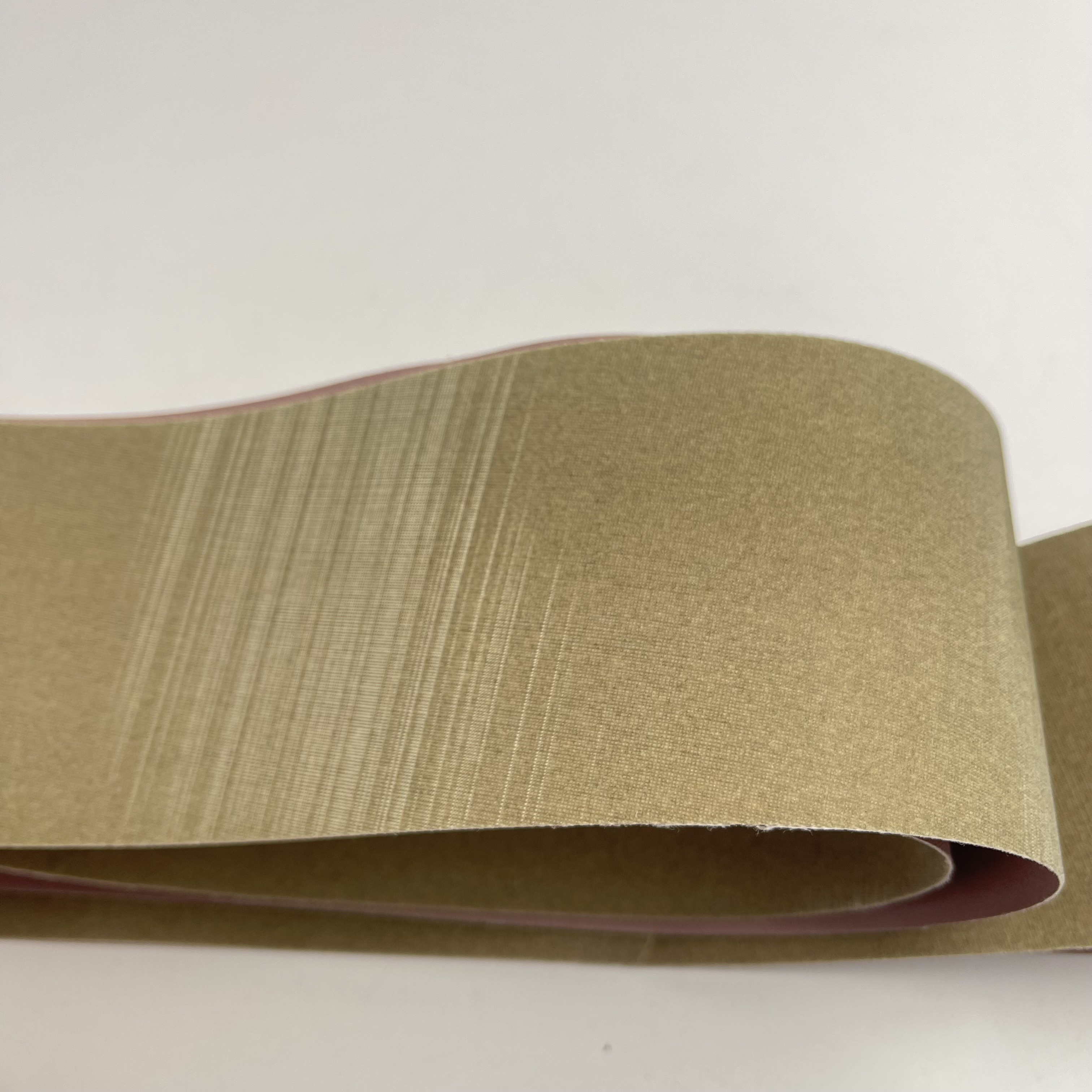

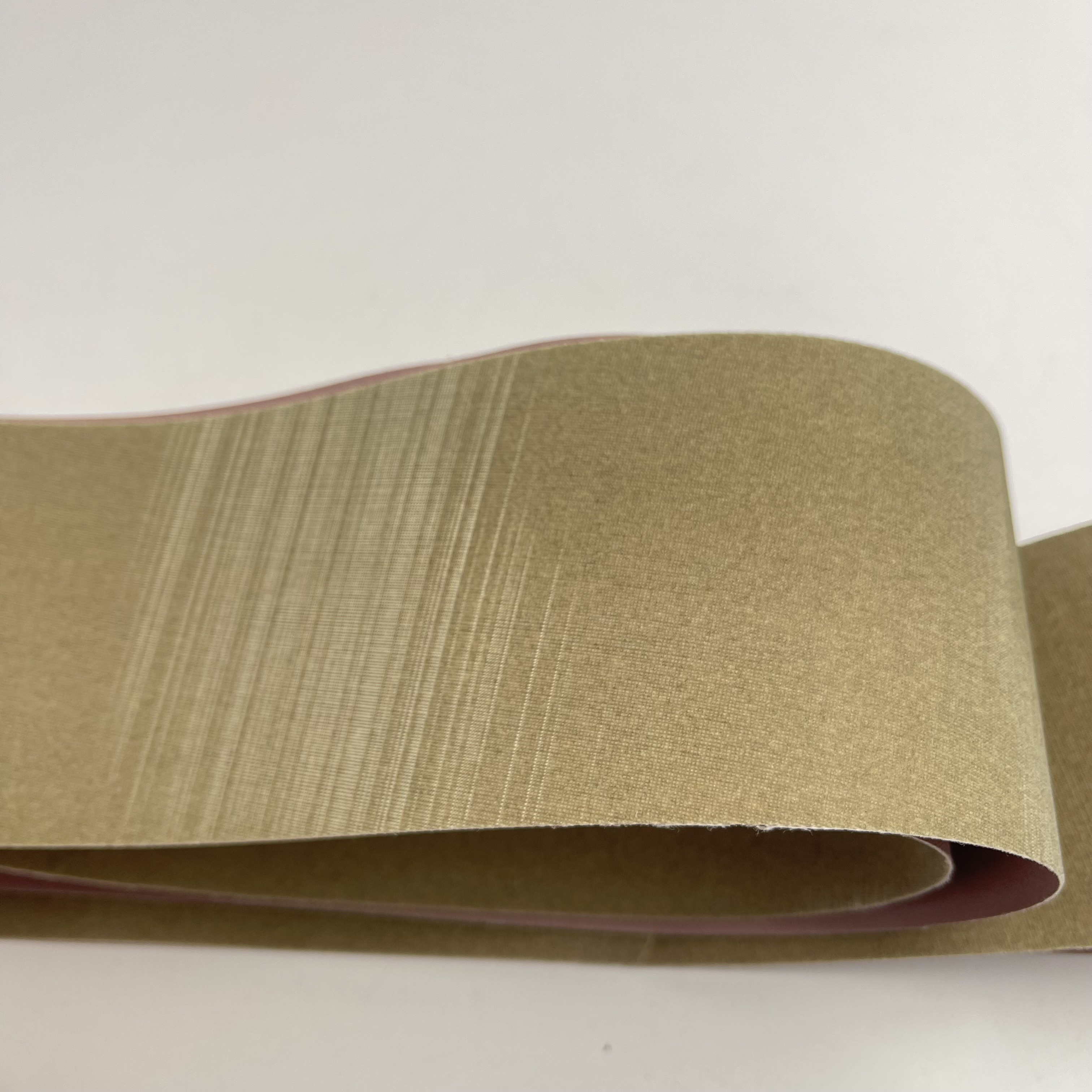

Trizact Cloth Belt 307EA

Nice Top

Trizact Cloth Belt 307EA is a specially designed abrasive belt suitable for efficient grinding and dressing of metallic materials. Its pyramid-shaped grit arrangement provides a smooth, even grinding result with high durability and wear resistance. When using, attention should be paid to following relevant safety regulations and operating procedures to ensure safety and normal work.

The Trizact Cloth Belt 307EA delivers exceptional consistency in surface finishing thanks to its precision-engineered microreplicated structure. Each abrasive pyramid continuously exposes new cutting edges during use, ensuring stable cutting performance and uniform surface quality throughout the belt’s lifespan. This innovative design minimizes heat generation, reduces workpiece deformation, and achieves an excellent balance between cutting efficiency and surface smoothness, making it ideal for precision metalworking applications.

Product Parameters

| Abrasive Material | Precision Shaped Ceramic |

| Application | Wide Belt Sanding, Flat Finishing, Grinding, Deburring, Finishing, Flat Part Grinding, Blending, Weld Grinding, Centerless & Cylindrical Grinding, Setting the Grain, Weld Removal |

| Brands | Nice Top |

| Backing Material | Polyester Cloth |

| Industries | Primary Metal, Castings and Forging, General Industrial, Aerospace, Metalworking, Precision Grinding & Finishing, Transportation & Heavy Equipment |

| Equipment - Machines | Portable Belt Sanders, Wide Belt Sanders, Mould Sanders, Edge Sanders, Profile Sanders |

| Place of origin | China |

| Customized support | OEM, ODM |

Features

Pyramid Shape

The abrasive grains of the Pyramid Abrasive Belt 307EA are arranged in a unique pyramid structure. This precision-engineered design ensures that new sharp cutting edges are constantly exposed as the top layer wears down. As a result, the belt maintains high grinding efficiency throughout its lifespan and delivers a consistent surface finish. The pyramid configuration also minimizes clogging and heat buildup, improving both performance stability and service life in continuous operations.

Efficient Grinding

The 307EA abrasive belt is specifically designed for high-efficiency grinding and dressing applications. Its microreplicated abrasive structure allows it to quickly remove rust, oxidation, and irregularities on metal surfaces with minimal effort. Even under high pressure, it maintains stable cutting power without overheating or damaging the workpiece. This efficiency makes it ideal for industrial environments that demand fast material removal and uniform results, such as metal fabrication or tool finishing.

Suitable for Multiple Materials

Engineered for versatility, the Pyramid Abrasive Belt 307EA is compatible with a wide range of materials including steel, aluminum, copper, and stainless steel. Its advanced abrasive formulation ensures reliable performance across soft and hard metals alike, adapting seamlessly to different substrates. Whether used for coarse grinding, fine finishing, or surface preparation, it maintains excellent performance consistency, making it a valuable choice for multi-purpose workshops and production lines.

Smooth and Uniform Grinding Effect

Thanks to its pyramid-shaped abrasive pattern, the 307EA belt provides exceptionally smooth and uniform grinding results. As each pyramid layer wears evenly, fresh abrasive particles continuously appear, ensuring a controlled and predictable cutting rate. This minimizes the risk of uneven wear, surface gouging, or inconsistent texture—problems often encountered with traditional abrasive belts. The result is a cleaner, more refined surface finish suitable for pre-polishing or precision finishing tasks.

Durability

Built with high wear resistance and superior material bonding, the Pyramid Abrasive Belt 307EA offers outstanding durability in demanding applications. It can withstand long working cycles without significant performance loss, maintaining sharpness and efficiency over time. This durability reduces the frequency of belt changes, lowers operating costs, and enhances productivity. Its reliable performance and extended lifespan make it a cost-effective solution for both manual and automated grinding systems.

Applications

Precision Metal Finishing and Surface Conditioning

The Trizact Cloth Belt provides exceptional consistency in precision metal finishing. Its microreplicated abrasive structure ensures uniform cutting and repeatable results, ideal for aerospace and automotive components requiring tight tolerances. Unlike traditional abrasives, Trizact maintains constant sharpness for longer life and consistent finishes. It removes fine scratches and oxidation from stainless steel, titanium, or aluminum without distorting geometry. With low heat generation and smooth control, it delivers superior surface integrity and reduced rework, making it a trusted solution for high-precision manufacturing.

Automotive Paint Preparation and Refinishing

In automotive production and repair, the Trizact Cloth Belt ensures smooth, defect-free surfaces before painting. Its uniform abrasive pattern removes imperfections from primers, clear coats, and metals efficiently, leaving a fine, swirl-free finish. The belt minimizes over-sanding risks, reducing material waste and polishing time. Its flexible cloth backing adapts to curves and contours, ensuring even results on fenders, bumpers, and panels. Whether for OEM lines or body shops, Trizact enables fast, clean, and consistent refinishing for premium, showroom-quality finishes.

Aerospace Component Polishing and Deburring

The Trizact Cloth Belt meets the strict demands of aerospace finishing, offering reliable results for turbine blades, landing gear, and precision components. Its microstructured abrasives ensure consistent performance and cooler operation, protecting high-value materials like titanium and Inconel. The belt efficiently removes burrs and machining marks while preserving dimensional accuracy. Compatible with robotic and automated systems, it improves productivity, reduces manual labor, and ensures compliance with aerospace surface standards for safety and reliability.

Medical Device Polishing and Surface Refinement

In medical device manufacturing, the Trizact Cloth Belt delivers ultra-smooth, hygienic surfaces on implants and surgical tools. Its controlled abrasive structure ensures consistent fine finishes that meet medical-grade roughness standards. By minimizing heat and friction, it prevents discoloration and material degradation. The belt’s predictable wear and long life make it ideal for automated polishing of stainless steel or titanium instruments, helping manufacturers achieve precise, sterile, and visually flawless surfaces with reduced processing time.

Tool and Die Maintenance, Mold Polishing, and Refurbishment

The Trizact Cloth Belt offers superior performance in tooling and mold maintenance. It effectively removes machining marks, EDM scale, and oxidation while maintaining dimensional accuracy. The flexible belt conforms to complex geometries and fine contours, enabling precise polishing of dies and molds. With its consistent cutting action and long service life, it minimizes rework and enhances productivity. Ideal for injection molds, stamping dies, and precision tools, Trizact ensures smooth, uniform finishes that extend equipment lifespan.

Frequently Asked Questions (FAQ)

Q1: why should you buy from us not from other suppliers?

A: Nice Top has strong capability to design and produce world top convolute wheel, unitized wheel,bristle brushes & discs,non woven Polishing wheel,laser braze finishing wheel etc. We give you competitive price and never comprise to quality.

Q2: Can it be used on both manual tools and automated systems?

A: Yes, it is compatible with handheld grinders as well as robotic finishing systems commonly used in automotive assembly lines.

Q3: Is it suitable for aluminum and stainless steel?

A: Absolutely. The wheel works effectively on aluminum alloys, stainless steel, silicon bronze, and other metals commonly used in laser brazing.

Q4: How long does one wheel last?

A: Service life depends on application conditions, but thanks to the cotton-fiber construction and premium abrasives, it lasts significantly longer than conventional finishing wheels.

Q5: Can you provide product samples before bulk orders?

A: Yes, we can supply samples for testing to ensure the wheel meets your application requirements.

Notice

The safety performance of Nice Top grinding wheel is strictly tested and has clear safety operation instructions. However, it is still essential to install and use it properly and stick to the safety instruction. Each product is labeled with the MOS: Maximum Operating Speed. The actual operating speed can not exceed the maximum operating speed.

Moreover, Please also pay attention to the mechanical protection, wear the mask, safety glass and safety shoe. Pay attention to the ventilation of the workshop.

When operating convolute wheel, we should pay special attention to the arrowhead marked on the product, and the direction of the arrow is the rotation direction of the product. The product must be operated with the right direction.

In addition to high performance, the Trizact Cloth Belt 307EA offers strong adaptability to various substrates, including stainless steel, aluminum, and alloy components. Its flexible cloth backing ensures smooth operation even on curved or irregular surfaces, while its long service life helps reduce tool change frequency and production downtime. The belt is widely applied in industries such as aerospace, automotive, and precision engineering, where consistent finish and high productivity are essential.

Due to variations in product models, specifications, and production lead times, prices may differ across different items. To receive an accurate quotation, we sincerely invite you to contact us with detailed product information, such as model number, dimensions, and estimated purchase quantity. Based on the details provided, we will offer a customized price quotation. We are also open to offering reasonable discounts depending on your order volume or specific requirements.

We warmly welcome your inquiries and are committed to working with you to find the most suitable and cost-effective solution.

Trizact Cloth Belt 307EA is a specially designed abrasive belt suitable for efficient grinding and dressing of metallic materials. Its pyramid-shaped grit arrangement provides a smooth, even grinding result with high durability and wear resistance. When using, attention should be paid to following relevant safety regulations and operating procedures to ensure safety and normal work.

The Trizact Cloth Belt 307EA delivers exceptional consistency in surface finishing thanks to its precision-engineered microreplicated structure. Each abrasive pyramid continuously exposes new cutting edges during use, ensuring stable cutting performance and uniform surface quality throughout the belt’s lifespan. This innovative design minimizes heat generation, reduces workpiece deformation, and achieves an excellent balance between cutting efficiency and surface smoothness, making it ideal for precision metalworking applications.

Product Parameters

| Abrasive Material | Precision Shaped Ceramic |

| Application | Wide Belt Sanding, Flat Finishing, Grinding, Deburring, Finishing, Flat Part Grinding, Blending, Weld Grinding, Centerless & Cylindrical Grinding, Setting the Grain, Weld Removal |

| Brands | Nice Top |

| Backing Material | Polyester Cloth |

| Industries | Primary Metal, Castings and Forging, General Industrial, Aerospace, Metalworking, Precision Grinding & Finishing, Transportation & Heavy Equipment |

| Equipment - Machines | Portable Belt Sanders, Wide Belt Sanders, Mould Sanders, Edge Sanders, Profile Sanders |

| Place of origin | China |

| Customized support | OEM, ODM |

Features

Pyramid Shape

The abrasive grains of the Pyramid Abrasive Belt 307EA are arranged in a unique pyramid structure. This precision-engineered design ensures that new sharp cutting edges are constantly exposed as the top layer wears down. As a result, the belt maintains high grinding efficiency throughout its lifespan and delivers a consistent surface finish. The pyramid configuration also minimizes clogging and heat buildup, improving both performance stability and service life in continuous operations.

Efficient Grinding

The 307EA abrasive belt is specifically designed for high-efficiency grinding and dressing applications. Its microreplicated abrasive structure allows it to quickly remove rust, oxidation, and irregularities on metal surfaces with minimal effort. Even under high pressure, it maintains stable cutting power without overheating or damaging the workpiece. This efficiency makes it ideal for industrial environments that demand fast material removal and uniform results, such as metal fabrication or tool finishing.

Suitable for Multiple Materials

Engineered for versatility, the Pyramid Abrasive Belt 307EA is compatible with a wide range of materials including steel, aluminum, copper, and stainless steel. Its advanced abrasive formulation ensures reliable performance across soft and hard metals alike, adapting seamlessly to different substrates. Whether used for coarse grinding, fine finishing, or surface preparation, it maintains excellent performance consistency, making it a valuable choice for multi-purpose workshops and production lines.

Smooth and Uniform Grinding Effect

Thanks to its pyramid-shaped abrasive pattern, the 307EA belt provides exceptionally smooth and uniform grinding results. As each pyramid layer wears evenly, fresh abrasive particles continuously appear, ensuring a controlled and predictable cutting rate. This minimizes the risk of uneven wear, surface gouging, or inconsistent texture—problems often encountered with traditional abrasive belts. The result is a cleaner, more refined surface finish suitable for pre-polishing or precision finishing tasks.

Durability

Built with high wear resistance and superior material bonding, the Pyramid Abrasive Belt 307EA offers outstanding durability in demanding applications. It can withstand long working cycles without significant performance loss, maintaining sharpness and efficiency over time. This durability reduces the frequency of belt changes, lowers operating costs, and enhances productivity. Its reliable performance and extended lifespan make it a cost-effective solution for both manual and automated grinding systems.

Applications

Precision Metal Finishing and Surface Conditioning

The Trizact Cloth Belt provides exceptional consistency in precision metal finishing. Its microreplicated abrasive structure ensures uniform cutting and repeatable results, ideal for aerospace and automotive components requiring tight tolerances. Unlike traditional abrasives, Trizact maintains constant sharpness for longer life and consistent finishes. It removes fine scratches and oxidation from stainless steel, titanium, or aluminum without distorting geometry. With low heat generation and smooth control, it delivers superior surface integrity and reduced rework, making it a trusted solution for high-precision manufacturing.

Automotive Paint Preparation and Refinishing

In automotive production and repair, the Trizact Cloth Belt ensures smooth, defect-free surfaces before painting. Its uniform abrasive pattern removes imperfections from primers, clear coats, and metals efficiently, leaving a fine, swirl-free finish. The belt minimizes over-sanding risks, reducing material waste and polishing time. Its flexible cloth backing adapts to curves and contours, ensuring even results on fenders, bumpers, and panels. Whether for OEM lines or body shops, Trizact enables fast, clean, and consistent refinishing for premium, showroom-quality finishes.

Aerospace Component Polishing and Deburring

The Trizact Cloth Belt meets the strict demands of aerospace finishing, offering reliable results for turbine blades, landing gear, and precision components. Its microstructured abrasives ensure consistent performance and cooler operation, protecting high-value materials like titanium and Inconel. The belt efficiently removes burrs and machining marks while preserving dimensional accuracy. Compatible with robotic and automated systems, it improves productivity, reduces manual labor, and ensures compliance with aerospace surface standards for safety and reliability.

Medical Device Polishing and Surface Refinement

In medical device manufacturing, the Trizact Cloth Belt delivers ultra-smooth, hygienic surfaces on implants and surgical tools. Its controlled abrasive structure ensures consistent fine finishes that meet medical-grade roughness standards. By minimizing heat and friction, it prevents discoloration and material degradation. The belt’s predictable wear and long life make it ideal for automated polishing of stainless steel or titanium instruments, helping manufacturers achieve precise, sterile, and visually flawless surfaces with reduced processing time.

Tool and Die Maintenance, Mold Polishing, and Refurbishment

The Trizact Cloth Belt offers superior performance in tooling and mold maintenance. It effectively removes machining marks, EDM scale, and oxidation while maintaining dimensional accuracy. The flexible belt conforms to complex geometries and fine contours, enabling precise polishing of dies and molds. With its consistent cutting action and long service life, it minimizes rework and enhances productivity. Ideal for injection molds, stamping dies, and precision tools, Trizact ensures smooth, uniform finishes that extend equipment lifespan.

Frequently Asked Questions (FAQ)

Q1: why should you buy from us not from other suppliers?

A: Nice Top has strong capability to design and produce world top convolute wheel, unitized wheel,bristle brushes & discs,non woven Polishing wheel,laser braze finishing wheel etc. We give you competitive price and never comprise to quality.

Q2: Can it be used on both manual tools and automated systems?

A: Yes, it is compatible with handheld grinders as well as robotic finishing systems commonly used in automotive assembly lines.

Q3: Is it suitable for aluminum and stainless steel?

A: Absolutely. The wheel works effectively on aluminum alloys, stainless steel, silicon bronze, and other metals commonly used in laser brazing.

Q4: How long does one wheel last?

A: Service life depends on application conditions, but thanks to the cotton-fiber construction and premium abrasives, it lasts significantly longer than conventional finishing wheels.

Q5: Can you provide product samples before bulk orders?

A: Yes, we can supply samples for testing to ensure the wheel meets your application requirements.

Notice

The safety performance of Nice Top grinding wheel is strictly tested and has clear safety operation instructions. However, it is still essential to install and use it properly and stick to the safety instruction. Each product is labeled with the MOS: Maximum Operating Speed. The actual operating speed can not exceed the maximum operating speed.

Moreover, Please also pay attention to the mechanical protection, wear the mask, safety glass and safety shoe. Pay attention to the ventilation of the workshop.

When operating convolute wheel, we should pay special attention to the arrowhead marked on the product, and the direction of the arrow is the rotation direction of the product. The product must be operated with the right direction.

In addition to high performance, the Trizact Cloth Belt 307EA offers strong adaptability to various substrates, including stainless steel, aluminum, and alloy components. Its flexible cloth backing ensures smooth operation even on curved or irregular surfaces, while its long service life helps reduce tool change frequency and production downtime. The belt is widely applied in industries such as aerospace, automotive, and precision engineering, where consistent finish and high productivity are essential.

Due to variations in product models, specifications, and production lead times, prices may differ across different items. To receive an accurate quotation, we sincerely invite you to contact us with detailed product information, such as model number, dimensions, and estimated purchase quantity. Based on the details provided, we will offer a customized price quotation. We are also open to offering reasonable discounts depending on your order volume or specific requirements.

We warmly welcome your inquiries and are committed to working with you to find the most suitable and cost-effective solution.