| Size: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Availability: | |||||||||

| Quantity: | |||||||||

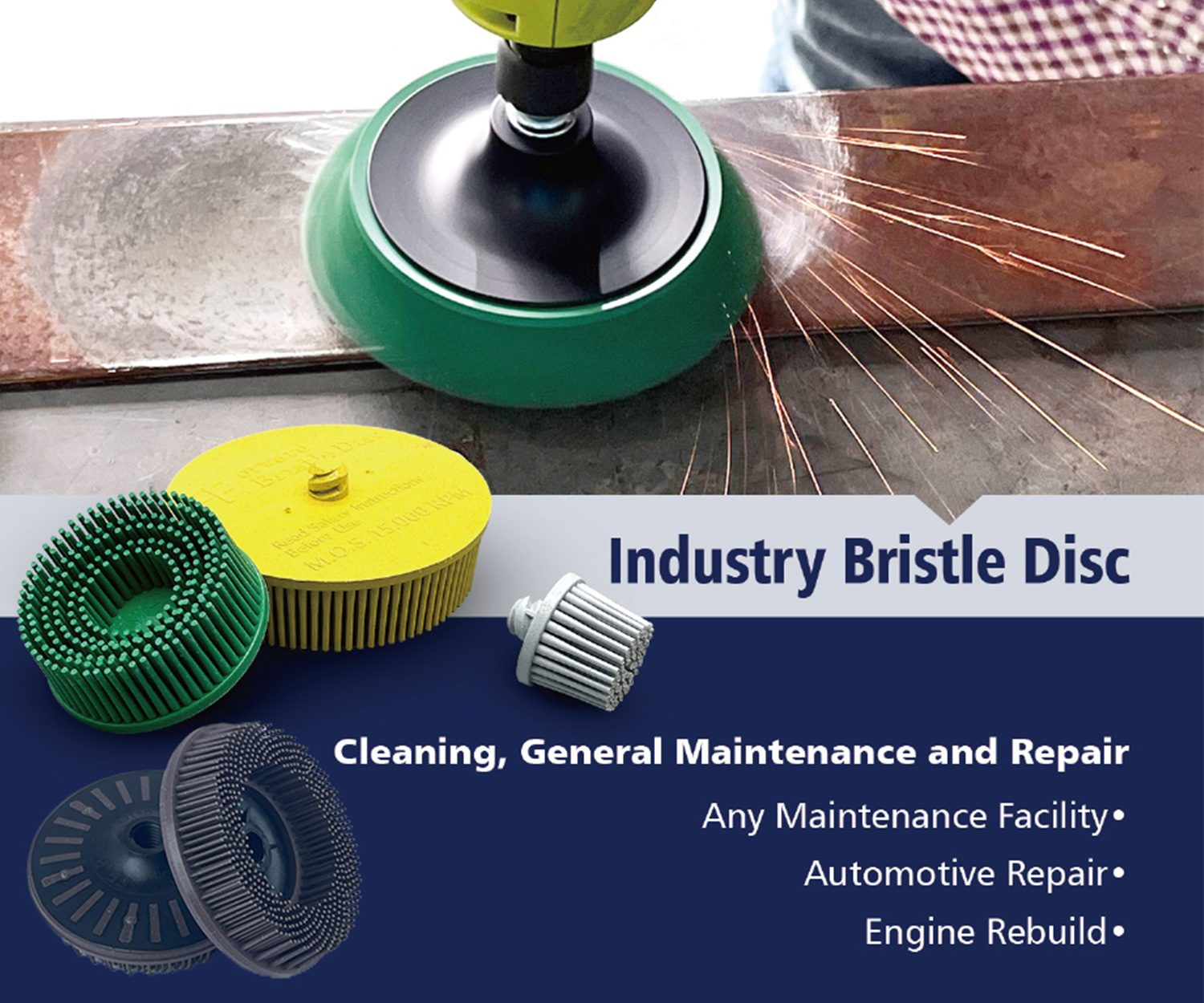

| this bristle disc is designed for use on all metals. With its high-quality construction, it efficiently removes rust, paint, and corrosion, ensuring a smooth surface. Ideal for industrial applications, it offers excellent performance and longevity. Compared with 3M's, our surface treatment effect is better, the use loss is less, the service life is longer, and it has a preferential price. | |||||||||

2" Bristle Disc

Nice Top

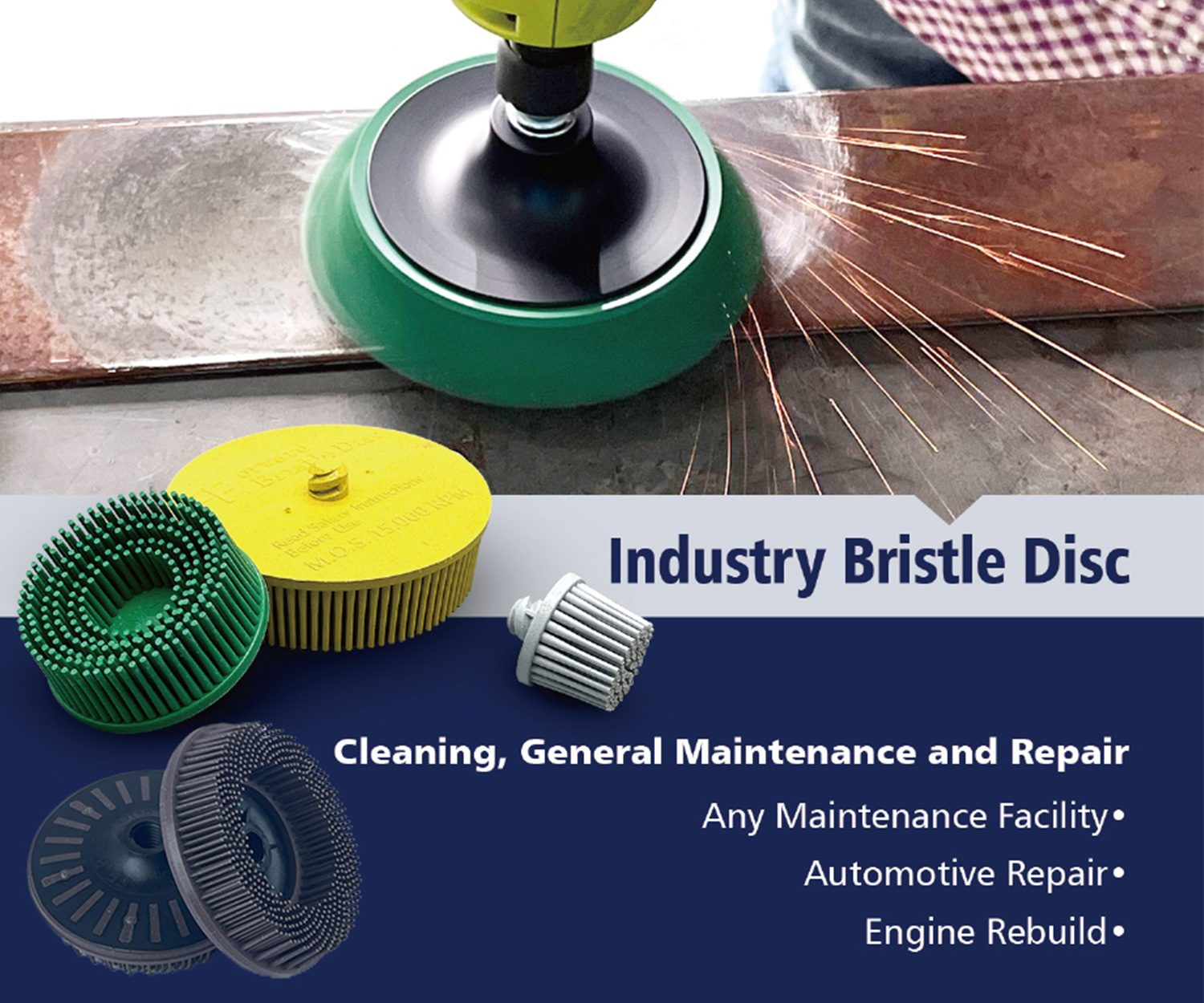

Bristle discs are innovative tools for metal surface treatment and polishing. The bristle disc uses ceramic aluminum oxide mixed abrasives and is installed on the backing. The backing can be connected to power tools such as angle grinders or desktop motors.

Bristle discs offer exceptional flexibility, allowing the abrasive bristles to conform to irregular or curved surfaces. This unique structure ensures consistent contact with the workpiece, resulting in uniform material removal and a smooth, polished finish. Their adaptability makes them ideal for precision tasks, such as deburring edges, cleaning weld seams, and refining detailed metal components without damaging the surrounding area.

Bristle discs provide long-lasting performance due to their high-quality ceramic aluminum oxide abrasives. The robust backing ensures stability during high-speed operation, while the carefully bonded bristles resist wear and maintain cutting efficiency over time. These discs reduce downtime and maintenance costs, making them an efficient and reliable choice for industrial, automotive, and metal fabrication applications.

Product Parameters

| Abrasive Material | Ceramic |

| Application | Strip, Deburr, Blend, Finish, Polish, Clean, Remove Coatings |

| Grit | 50#,80#,120# |

| Brands | Nice Top |

| Diameter | 2inch |

| Maximum Speed | 12000 rpm |

| Industries | General Industrial, Aerospace, Metalworking, Automotive, Transportation & Automotive Applications |

| For Use With | Common electric,Pneumatic tools,Rotary tool,Angle Grinder,Die Grinder,Drill |

| For Use On | Aluminum, Brass, Bronze, Carbon steel, Cast iron, Stainless steel, and other metals |

Key Features and Benefits

Versatility

The bristle disc is suitable for a wide range of metal substrates, including steel, aluminum, copper, and other alloys. Its flexible yet durable bristles effectively remove paint, rust, and oxidation while maintaining the integrity of the base material. This versatility makes it an excellent choice for applications in automotive repair, metal fabrication, ship maintenance, and machinery restoration. Whether for heavy-duty cleaning or delicate surface finishing, the bristle disc adapts perfectly to different materials and project needs.

Professional Removal

The high-strength, precisely molded bristles provide powerful cleaning and consistent surface treatment. They efficiently remove rust, oxide layers, weld discoloration, and stubborn coatings without causing deep scratches or deformation. Compared with wire brushes or sanding discs, the bristle disc ensures a smoother, more uniform finish, leaving surfaces ready for painting, coating, or further polishing.

Durability

Made from premium-grade ceramic and aluminum oxide abrasives, the bristle disc delivers extended service life and stable performance even under continuous operation. The unique combination of materials offers excellent wear resistance, load resistance, and heat dissipation, ensuring the disc remains effective longer than traditional abrasive tools. This means fewer replacements, lower operational costs, and improved work efficiency over time.

Easy to Operate

Designed for both professionals and beginners, the bristle disc is simple to install and use. Once securely attached to a rotary or pneumatic tool, just keep it in place and apply light pressure — no need for excessive force. This allows for precise control and minimal risk of damaging the workpiece, even during extended polishing or cleaning tasks. Its smooth, balanced rotation helps reduce operator fatigue and enhances comfort during use.

Saves Time

The bristle disc supports quick-change functionality, making it easy to switch between different grits or disc types during multi-step finishing processes. Its consistent performance reduces the need for repeated passes, allowing users to complete cleaning, deburring, and polishing tasks faster. The time saved translates into higher productivity and more efficient workflow across industrial or maintenance settings.

Applications

Surface Cleaning

Ideal for removing rust, paint, corrosion, scale, and oxidation from metal, wood, or composite materials. Bristle discs deliver clean surfaces without damaging the underlying material.

Polishing and Finishing

Perfect for achieving smooth, uniform finishes on metal, wood, or plastic parts. They effectively remove minor scratches, surface imperfections, and residues for a refined final appearance.

Deburring

Efficiently removes burrs, sharp edges, and excess material from machined or molded components, improving part safety, accuracy, and assembly quality.

Blending

Excellent for smoothing weld seams, transitions, and uneven surfaces. The discs produce a consistent blended finish that prepares workpieces for painting, coating, or plating.

Usage Tips

Safety First

Always prioritize safety during operation. Wear protective goggles, gloves, and face shields to guard against flying bristles, metal debris, and sparks. Ensure the work area is well-ventilated and that the tool is properly secured before use. Regularly inspect the disc for wear or damage to prevent accidents and maintain consistent performance.

Select the Right Size

Choose the appropriate disc diameter and bristle thickness according to your specific application — smaller discs are ideal for tight spaces or detailed work, while larger discs provide faster coverage on flat or broad surfaces. Selecting the correct size and grit level ensures optimal cleaning efficiency, reduced material waste, and superior finishing results.

Control Speed

When using tools such as angle grinders, rotary tools, or pneumatic sanders, operate within the manufacturer’s recommended RPM range. Excessive speed or pressure can cause premature wear or excessive heat buildup, which may affect surface quality. Maintaining steady speed and light pressure helps achieve consistent, uniform finishing while extending the life of the bristle disc.

Frequently Asked Questions (FAQ)

Q1: why should you buy from us not from other suppliers?

A: Nice Top has strong capability to design and produce world top convolute wheel, unitized wheel,bristle brushes & discs,non woven Polishing wheel,laser braze finishing wheel etc. We give you competitive price and never comprise to quality.

Q2: Can it be used on both manual tools and automated systems?

A: Yes, it is compatible with handheld grinders as well as robotic finishing systems commonly used in automotive assembly lines.

Q3: Is it suitable for aluminum and stainless steel?

A: Absolutely. The wheel works effectively on aluminum alloys, stainless steel, silicon bronze, and other metals commonly used in laser brazing.

Q4: How long does one wheel last?

A: Service life depends on application conditions, but thanks to the cotton-fiber construction and premium abrasives, it lasts significantly longer than conventional finishing wheels.

Q5: Can you provide product samples before bulk orders?

A: Yes, we can supply samples for testing to ensure the wheel meets your application requirements.

Notice

The safety performance of Nice Top grinding wheel is strictly tested and has clear safety operation instructions. However, it is still essential to install and use it properly and stick to the safety instruction. Each product is labeled with the MOS: Maximum Operating Speed. The actual operating speed can not exceed the maximum operating speed.

Moreover, Please also pay attention to the mechanical protection, wear the mask, safety glass and safety shoe. Pay attention to the ventilation of the workshop.

Whether you're in high-volume manufacturing or custom fabrication, our Convolute Wheels help you improve efficiency, surface quality, and process consistency. They're trusted by professionals across industries to deliver the perfect balance of performance, precision, and longevity.

Contact us today to discuss your specific needs, request samples, or get a tailored quotation—we’re here to support your finishing success.

Bristle discs are innovative tools for metal surface treatment and polishing. The bristle disc uses ceramic aluminum oxide mixed abrasives and is installed on the backing. The backing can be connected to power tools such as angle grinders or desktop motors.

Bristle discs offer exceptional flexibility, allowing the abrasive bristles to conform to irregular or curved surfaces. This unique structure ensures consistent contact with the workpiece, resulting in uniform material removal and a smooth, polished finish. Their adaptability makes them ideal for precision tasks, such as deburring edges, cleaning weld seams, and refining detailed metal components without damaging the surrounding area.

Bristle discs provide long-lasting performance due to their high-quality ceramic aluminum oxide abrasives. The robust backing ensures stability during high-speed operation, while the carefully bonded bristles resist wear and maintain cutting efficiency over time. These discs reduce downtime and maintenance costs, making them an efficient and reliable choice for industrial, automotive, and metal fabrication applications.

Product Parameters

| Abrasive Material | Ceramic |

| Application | Strip, Deburr, Blend, Finish, Polish, Clean, Remove Coatings |

| Grit | 50#,80#,120# |

| Brands | Nice Top |

| Diameter | 2inch |

| Maximum Speed | 12000 rpm |

| Industries | General Industrial, Aerospace, Metalworking, Automotive, Transportation & Automotive Applications |

| For Use With | Common electric,Pneumatic tools,Rotary tool,Angle Grinder,Die Grinder,Drill |

| For Use On | Aluminum, Brass, Bronze, Carbon steel, Cast iron, Stainless steel, and other metals |

Key Features and Benefits

Versatility

The bristle disc is suitable for a wide range of metal substrates, including steel, aluminum, copper, and other alloys. Its flexible yet durable bristles effectively remove paint, rust, and oxidation while maintaining the integrity of the base material. This versatility makes it an excellent choice for applications in automotive repair, metal fabrication, ship maintenance, and machinery restoration. Whether for heavy-duty cleaning or delicate surface finishing, the bristle disc adapts perfectly to different materials and project needs.

Professional Removal

The high-strength, precisely molded bristles provide powerful cleaning and consistent surface treatment. They efficiently remove rust, oxide layers, weld discoloration, and stubborn coatings without causing deep scratches or deformation. Compared with wire brushes or sanding discs, the bristle disc ensures a smoother, more uniform finish, leaving surfaces ready for painting, coating, or further polishing.

Durability

Made from premium-grade ceramic and aluminum oxide abrasives, the bristle disc delivers extended service life and stable performance even under continuous operation. The unique combination of materials offers excellent wear resistance, load resistance, and heat dissipation, ensuring the disc remains effective longer than traditional abrasive tools. This means fewer replacements, lower operational costs, and improved work efficiency over time.

Easy to Operate

Designed for both professionals and beginners, the bristle disc is simple to install and use. Once securely attached to a rotary or pneumatic tool, just keep it in place and apply light pressure — no need for excessive force. This allows for precise control and minimal risk of damaging the workpiece, even during extended polishing or cleaning tasks. Its smooth, balanced rotation helps reduce operator fatigue and enhances comfort during use.

Saves Time

The bristle disc supports quick-change functionality, making it easy to switch between different grits or disc types during multi-step finishing processes. Its consistent performance reduces the need for repeated passes, allowing users to complete cleaning, deburring, and polishing tasks faster. The time saved translates into higher productivity and more efficient workflow across industrial or maintenance settings.

Applications

Surface Cleaning

Ideal for removing rust, paint, corrosion, scale, and oxidation from metal, wood, or composite materials. Bristle discs deliver clean surfaces without damaging the underlying material.

Polishing and Finishing

Perfect for achieving smooth, uniform finishes on metal, wood, or plastic parts. They effectively remove minor scratches, surface imperfections, and residues for a refined final appearance.

Deburring

Efficiently removes burrs, sharp edges, and excess material from machined or molded components, improving part safety, accuracy, and assembly quality.

Blending

Excellent for smoothing weld seams, transitions, and uneven surfaces. The discs produce a consistent blended finish that prepares workpieces for painting, coating, or plating.

Usage Tips

Safety First

Always prioritize safety during operation. Wear protective goggles, gloves, and face shields to guard against flying bristles, metal debris, and sparks. Ensure the work area is well-ventilated and that the tool is properly secured before use. Regularly inspect the disc for wear or damage to prevent accidents and maintain consistent performance.

Select the Right Size

Choose the appropriate disc diameter and bristle thickness according to your specific application — smaller discs are ideal for tight spaces or detailed work, while larger discs provide faster coverage on flat or broad surfaces. Selecting the correct size and grit level ensures optimal cleaning efficiency, reduced material waste, and superior finishing results.

Control Speed

When using tools such as angle grinders, rotary tools, or pneumatic sanders, operate within the manufacturer’s recommended RPM range. Excessive speed or pressure can cause premature wear or excessive heat buildup, which may affect surface quality. Maintaining steady speed and light pressure helps achieve consistent, uniform finishing while extending the life of the bristle disc.

Frequently Asked Questions (FAQ)

Q1: why should you buy from us not from other suppliers?

A: Nice Top has strong capability to design and produce world top convolute wheel, unitized wheel,bristle brushes & discs,non woven Polishing wheel,laser braze finishing wheel etc. We give you competitive price and never comprise to quality.

Q2: Can it be used on both manual tools and automated systems?

A: Yes, it is compatible with handheld grinders as well as robotic finishing systems commonly used in automotive assembly lines.

Q3: Is it suitable for aluminum and stainless steel?

A: Absolutely. The wheel works effectively on aluminum alloys, stainless steel, silicon bronze, and other metals commonly used in laser brazing.

Q4: How long does one wheel last?

A: Service life depends on application conditions, but thanks to the cotton-fiber construction and premium abrasives, it lasts significantly longer than conventional finishing wheels.

Q5: Can you provide product samples before bulk orders?

A: Yes, we can supply samples for testing to ensure the wheel meets your application requirements.

Notice

The safety performance of Nice Top grinding wheel is strictly tested and has clear safety operation instructions. However, it is still essential to install and use it properly and stick to the safety instruction. Each product is labeled with the MOS: Maximum Operating Speed. The actual operating speed can not exceed the maximum operating speed.

Moreover, Please also pay attention to the mechanical protection, wear the mask, safety glass and safety shoe. Pay attention to the ventilation of the workshop.

Whether you're in high-volume manufacturing or custom fabrication, our Convolute Wheels help you improve efficiency, surface quality, and process consistency. They're trusted by professionals across industries to deliver the perfect balance of performance, precision, and longevity.

Contact us today to discuss your specific needs, request samples, or get a tailored quotation—we’re here to support your finishing success.