| Grit: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Availability: | |||||||||

| Quantity: | |||||||||

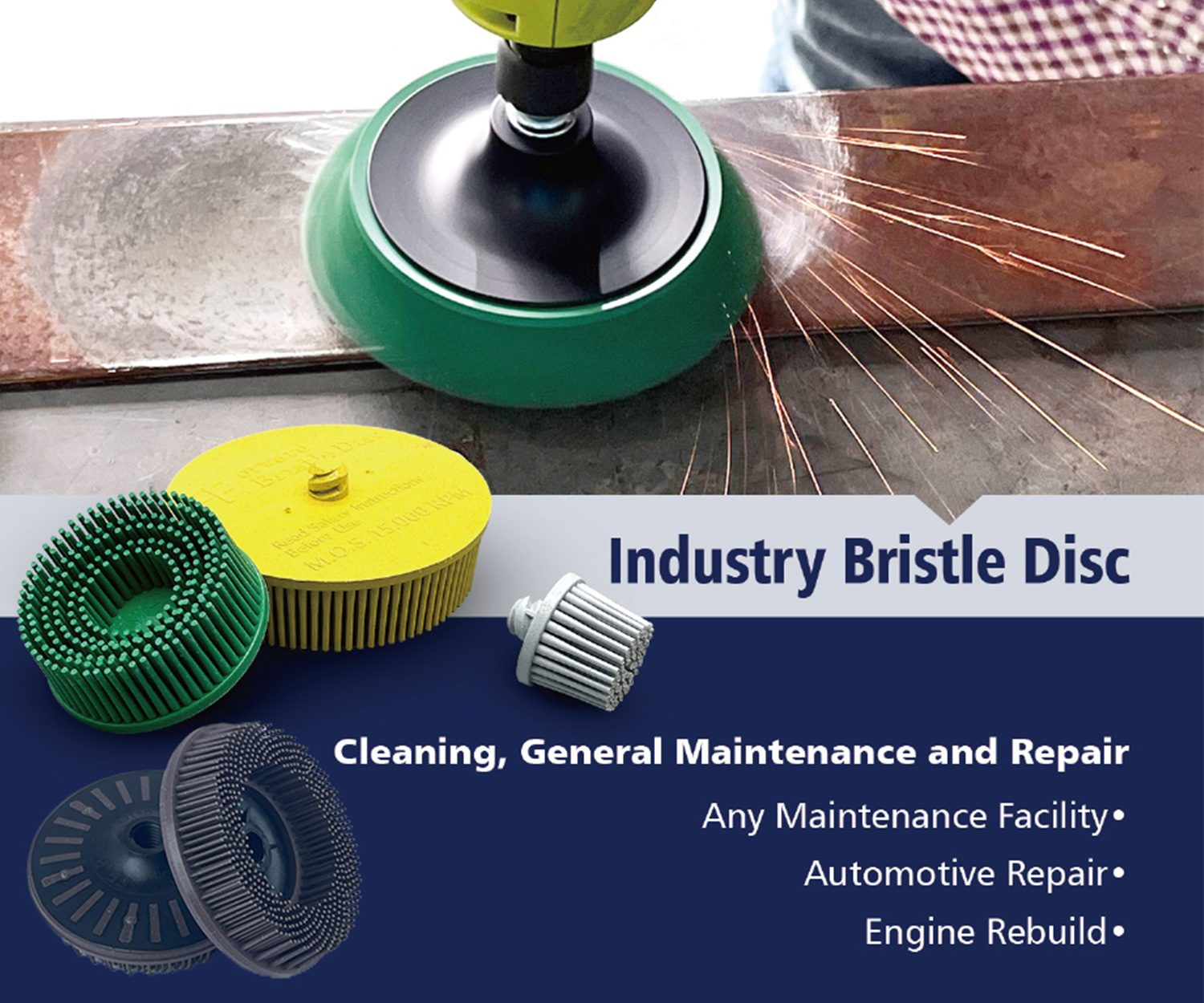

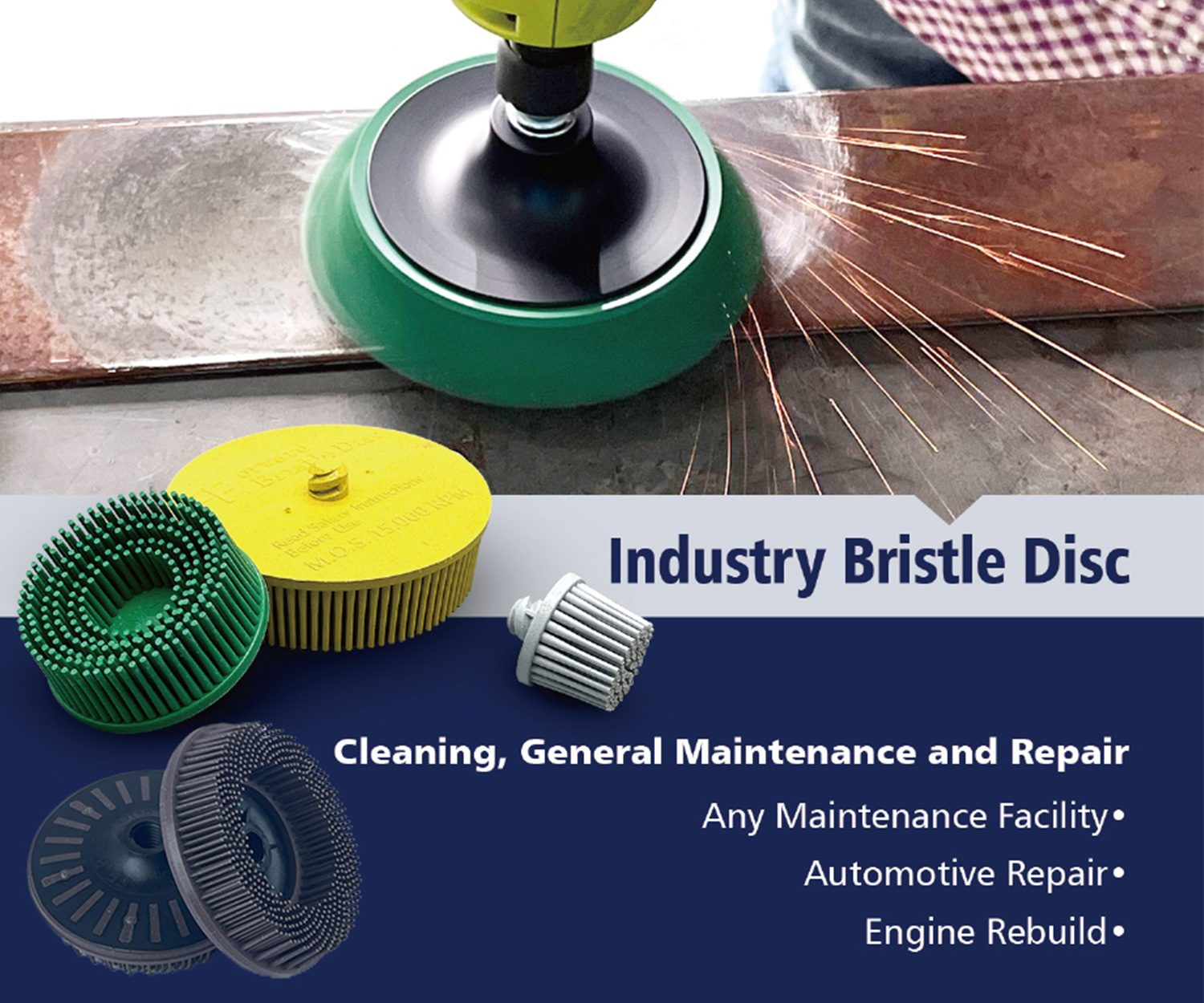

| Versatile and durable, this bristle disc is designed for use on all metals. With its high-quality construction, it efficiently removes rust, paint, and corrosion, ensuring a smooth surface. Ideal for industrial applications, it offers excellent performance and longevity. Compared with 3M's, our surface treatment effect is better, the use loss is less, the service life is longer, and it has a preferential price. | |||||||||

4-1/2" Bristle Disc

Nice Top

A bristle disc is a versatile abrasive tool utilized in various industries for surface preparation, cleaning, blending, and finishing tasks. It consists of a backing material, usually made of plastic or fiberglass, onto which abrasive-filled nylon ristles are securely attached. These bristles are embedded with abrasive particles, such as aluminum oxide or silicon carbide, which provide the cutting action necessary for material removal.

The design of the bristle disc allows for flexibility and conformability to irregular surfaces and contours, making it ideal for applications where precision and consistency are required. The bristles effectively reach into crevices, corners, and tight spaces that may be inaccessible with traditional abrasive tools, ensuring thorough and uniform surface treatment.

Bristle discs come in a variety of configurations to suit different applications and materials. They are available in different diameters, bristle lengths, and abrasive grit sizes. Coarser grit sizes are suitable for aggressive material removal and heavy-duty cleaning tasks, while finer grit sizes are used for achieving smoother finishes and surface blending.

Product Parameters

| Abrasive Material | Ceramic |

| Application | Strip, Deburr, Blend, Finish, Polish, Clean, Remove Coatings |

| Grit | 36#,50#,80#,120# |

| Brands | Nice Top |

| Diameter | 4.5inch 5/8“-11(Thread Size ) |

| Attachment Type | Threaded |

| Industries | General Industrial, Aerospace, Metalworking, Automotive, Transportation & Automotive Applications |

| For Use With | Common electric,Pneumatic tools,Rotary tool,Angle Grinder,Die Grinder,Drill |

| For Use On | Aluminum, Brass, Bronze, Carbon steel, Cast iron, Stainless steel, and other metals |

Aggressive Cutting Action

The embedded abrasive particles in the bristles provide highly effective material removal, allowing for fast and efficient surface cleaning, preparation, and shaping. This aggressive cutting action ensures that rust, paint, oxidation, and other surface contaminants are removed quickly, reducing manual effort and improving overall productivity. It is especially valuable for heavy-duty industrial and workshop applications where time and efficiency are critical.

Bristle discs deliver consistent and uniform surface finishes without gouging, scratching, or otherwise damaging the workpiece. The flexible bristles adapt to contours and uneven surfaces, maintaining smooth contact across the entire area. This makes them ideal for applications where surface aesthetics, precision, and quality are paramount, such as decorative metalwork, precision components, and finishing high-value materials.

These bristle discs are suitable for use on a wide variety of materials, including metals, wood, plastics, and composites. Their adaptable design allows them to perform multiple tasks such as deburring, polishing, cleaning, and surface preparation, making them suitable for diverse industrial, automotive, aerospace, and woodworking applications. This versatility helps operators rely on a single tool for multiple processes, improving workflow efficiency.

The durable construction of bristle discs ensures extended service life, maintaining consistent performance even under continuous or heavy-duty use. The wear-resistant bristles reduce the need for frequent replacements, minimizing downtime and operational costs. This longevity makes them a reliable choice for professional workshops, industrial production lines, and maintenance operations where efficiency and cost-effectiveness are important.

Ease of Use

Bristle discs are easy to install and use, requiring minimal setup and maintenance. They can be mounted on handheld angle grinders, die grinders, or other compatible power tools.

Thanks to its innovative radial design, the bristle disc offers superior flexibility and contouring capabilities. It effortlessly adapts to complex geometries, reaching into corners, crevices, grooves, and other hard-to-access areas. This makes it ideal for precision applications where uniformity and surface integrity are critical.

Available in a variety of sizes, bristle lengths, and abrasive grit levels, these discs can be tailored for aggressive material removal, heavy-duty rust or paint stripping, or for achieving ultra-smooth finishes during final polishing. Whether you're prepping metal for welding, cleaning up castings, or refining wood surfaces, bristle discs provide a safer, cooler-running, and longer-lasting alternative to traditional abrasives.

Applications

Effectively removes rust, old paint, oxidation, and other surface contaminants from metal parts and equipment, restoring clean, bare surfaces that are ready for further processing or finishing. The bristle discs adapt to contours and edges, ensuring thorough cleaning without damaging the underlying material, which improves preparation for coating, painting, or welding operations.

Ideal for post-weld cleanup, smoothing weld seams, and blending welded areas seamlessly with surrounding metal surfaces. This ensures a uniform, professional appearance while removing excess material and minor imperfections. The discs’ flexible bristles allow precise access to complex geometries and tight corners, producing consistent results on both large and intricate welded assemblies.

Efficiently removes burrs, sharp edges, and residual material left from cutting, stamping, or machining operations. This improves both operator safety and product precision, while ensuring parts fit accurately during assembly. The controlled abrasive action prevents over-removal, preserving dimensional accuracy and maintaining part integrity.

Creates an optimal surface texture that enhances paint, coating, or plating adhesion, ensuring a longer-lasting and more uniform finish. The discs remove minor surface imperfections, contamination, and oxidation while producing a smooth, clean substrate ready for decorative or protective finishes, improving the durability and aesthetics of the final product.

Efficiently eliminates grease, scale, and surface oxidation while conditioning the metal to provide a clean, smooth base. This preparation is ideal for subsequent finishing processes, including polishing, plating, or painting. By improving surface uniformity and cleanliness, the discs enhance the performance, longevity, and appearance of the treated parts.

Gently refines and polishes wooden surfaces, removing minor imperfections, scratches, and residues. Prepares the wood for staining, varnishing, or other decorative finishes without harming the natural grain. The controlled abrasive action ensures smooth, consistent results, making it suitable for furniture, flooring, cabinetry, and other fine woodworking applications.

Widely applied for maintenance, restoration, and finishing tasks across multiple industries—including automotive, aerospace, marine, and general manufacturing—providing consistent performance for cleaning, surface preparation, and finishing of metal components. The discs’ versatility and efficiency ensure high-quality results while reducing operational time and maintaining surface integrity on critical parts.

Operational Safety

When using the Bristle disc, you should pay attention to safety and avoid accidents such as bristles falling off, splashing or throwing.

According to the needs of the specific application, select the appropriate rotation speed and pressure to avoid excessive force or excessive rotation speed, which may cause surface damage or rapid wear of the bristles.

During use, regularly check the wear degree of the bristles and brush disc. If there is any damage or severe wear, replace it in time.

When using Bristle discs, follow the manufacturer's instructions and safety recommendations to ensure correct and safe operation.

Frequently Asked Questions (FAQ)

Q1: why should you buy from us not from other suppliers?

A: Nice Top has strong capability to design and produce world top convolute wheel, unitized wheel,bristle brushes & discs,non woven Polishing wheel,laser braze finishing wheel etc. We give you competitive price and never comprise to quality.

Q2: Can it be used on both manual tools and automated systems?

A: Yes, it is compatible with handheld grinders as well as robotic finishing systems commonly used in automotive assembly lines.

Q3: Is it suitable for aluminum and stainless steel?

A: Absolutely. The wheel works effectively on aluminum alloys, stainless steel, silicon bronze, and other metals commonly used in laser brazing.

Q4: How long does one wheel last?

A: Service life depends on application conditions, but thanks to the cotton-fiber construction and premium abrasives, it lasts significantly longer than conventional finishing wheels.

Q5: Can you provide product samples before bulk orders?

A: Yes, we can supply samples for testing to ensure the wheel meets your application requirements.

Notice

The safety performance of Nice Top grinding wheel is strictly tested and has clear safety operation instructions. However, it is still essential to install and use it properly and stick to the safety instruction. Each product is labeled with the MOS: Maximum Operating Speed. The actual operating speed can not exceed the maximum operating speed.

Moreover, Please also pay attention to the mechanical protection, wear the mask, safety glass and safety shoe. Pay attention to the ventilation of the workshop.

Due to variations in product models, specifications, and production lead times, prices may differ across different items. To receive an accurate quotation, we sincerely invite you to contact us with detailed product information, such as model number, dimensions, and estimated purchase quantity. Based on the details provided, we will offer a customized price quotation. We are also open to offering reasonable discounts depending on your order volume or specific requirements.

We warmly welcome your inquiries and are committed to working with you to find the most suitable and cost-effective solution.

A bristle disc is a versatile abrasive tool utilized in various industries for surface preparation, cleaning, blending, and finishing tasks. It consists of a backing material, usually made of plastic or fiberglass, onto which abrasive-filled nylon ristles are securely attached. These bristles are embedded with abrasive particles, such as aluminum oxide or silicon carbide, which provide the cutting action necessary for material removal.

The design of the bristle disc allows for flexibility and conformability to irregular surfaces and contours, making it ideal for applications where precision and consistency are required. The bristles effectively reach into crevices, corners, and tight spaces that may be inaccessible with traditional abrasive tools, ensuring thorough and uniform surface treatment.

Bristle discs come in a variety of configurations to suit different applications and materials. They are available in different diameters, bristle lengths, and abrasive grit sizes. Coarser grit sizes are suitable for aggressive material removal and heavy-duty cleaning tasks, while finer grit sizes are used for achieving smoother finishes and surface blending.

Product Parameters

| Abrasive Material | Ceramic |

| Application | Strip, Deburr, Blend, Finish, Polish, Clean, Remove Coatings |

| Grit | 36#,50#,80#,120# |

| Brands | Nice Top |

| Diameter | 4.5inch 5/8“-11(Thread Size ) |

| Attachment Type | Threaded |

| Industries | General Industrial, Aerospace, Metalworking, Automotive, Transportation & Automotive Applications |

| For Use With | Common electric,Pneumatic tools,Rotary tool,Angle Grinder,Die Grinder,Drill |

| For Use On | Aluminum, Brass, Bronze, Carbon steel, Cast iron, Stainless steel, and other metals |

Aggressive Cutting Action

The embedded abrasive particles in the bristles provide highly effective material removal, allowing for fast and efficient surface cleaning, preparation, and shaping. This aggressive cutting action ensures that rust, paint, oxidation, and other surface contaminants are removed quickly, reducing manual effort and improving overall productivity. It is especially valuable for heavy-duty industrial and workshop applications where time and efficiency are critical.

Bristle discs deliver consistent and uniform surface finishes without gouging, scratching, or otherwise damaging the workpiece. The flexible bristles adapt to contours and uneven surfaces, maintaining smooth contact across the entire area. This makes them ideal for applications where surface aesthetics, precision, and quality are paramount, such as decorative metalwork, precision components, and finishing high-value materials.

These bristle discs are suitable for use on a wide variety of materials, including metals, wood, plastics, and composites. Their adaptable design allows them to perform multiple tasks such as deburring, polishing, cleaning, and surface preparation, making them suitable for diverse industrial, automotive, aerospace, and woodworking applications. This versatility helps operators rely on a single tool for multiple processes, improving workflow efficiency.

The durable construction of bristle discs ensures extended service life, maintaining consistent performance even under continuous or heavy-duty use. The wear-resistant bristles reduce the need for frequent replacements, minimizing downtime and operational costs. This longevity makes them a reliable choice for professional workshops, industrial production lines, and maintenance operations where efficiency and cost-effectiveness are important.

Ease of Use

Bristle discs are easy to install and use, requiring minimal setup and maintenance. They can be mounted on handheld angle grinders, die grinders, or other compatible power tools.

Thanks to its innovative radial design, the bristle disc offers superior flexibility and contouring capabilities. It effortlessly adapts to complex geometries, reaching into corners, crevices, grooves, and other hard-to-access areas. This makes it ideal for precision applications where uniformity and surface integrity are critical.

Available in a variety of sizes, bristle lengths, and abrasive grit levels, these discs can be tailored for aggressive material removal, heavy-duty rust or paint stripping, or for achieving ultra-smooth finishes during final polishing. Whether you're prepping metal for welding, cleaning up castings, or refining wood surfaces, bristle discs provide a safer, cooler-running, and longer-lasting alternative to traditional abrasives.

Applications

Effectively removes rust, old paint, oxidation, and other surface contaminants from metal parts and equipment, restoring clean, bare surfaces that are ready for further processing or finishing. The bristle discs adapt to contours and edges, ensuring thorough cleaning without damaging the underlying material, which improves preparation for coating, painting, or welding operations.

Ideal for post-weld cleanup, smoothing weld seams, and blending welded areas seamlessly with surrounding metal surfaces. This ensures a uniform, professional appearance while removing excess material and minor imperfections. The discs’ flexible bristles allow precise access to complex geometries and tight corners, producing consistent results on both large and intricate welded assemblies.

Efficiently removes burrs, sharp edges, and residual material left from cutting, stamping, or machining operations. This improves both operator safety and product precision, while ensuring parts fit accurately during assembly. The controlled abrasive action prevents over-removal, preserving dimensional accuracy and maintaining part integrity.

Creates an optimal surface texture that enhances paint, coating, or plating adhesion, ensuring a longer-lasting and more uniform finish. The discs remove minor surface imperfections, contamination, and oxidation while producing a smooth, clean substrate ready for decorative or protective finishes, improving the durability and aesthetics of the final product.

Efficiently eliminates grease, scale, and surface oxidation while conditioning the metal to provide a clean, smooth base. This preparation is ideal for subsequent finishing processes, including polishing, plating, or painting. By improving surface uniformity and cleanliness, the discs enhance the performance, longevity, and appearance of the treated parts.

Gently refines and polishes wooden surfaces, removing minor imperfections, scratches, and residues. Prepares the wood for staining, varnishing, or other decorative finishes without harming the natural grain. The controlled abrasive action ensures smooth, consistent results, making it suitable for furniture, flooring, cabinetry, and other fine woodworking applications.

Widely applied for maintenance, restoration, and finishing tasks across multiple industries—including automotive, aerospace, marine, and general manufacturing—providing consistent performance for cleaning, surface preparation, and finishing of metal components. The discs’ versatility and efficiency ensure high-quality results while reducing operational time and maintaining surface integrity on critical parts.

Operational Safety

When using the Bristle disc, you should pay attention to safety and avoid accidents such as bristles falling off, splashing or throwing.

According to the needs of the specific application, select the appropriate rotation speed and pressure to avoid excessive force or excessive rotation speed, which may cause surface damage or rapid wear of the bristles.

During use, regularly check the wear degree of the bristles and brush disc. If there is any damage or severe wear, replace it in time.

When using Bristle discs, follow the manufacturer's instructions and safety recommendations to ensure correct and safe operation.

Frequently Asked Questions (FAQ)

Q1: why should you buy from us not from other suppliers?

A: Nice Top has strong capability to design and produce world top convolute wheel, unitized wheel,bristle brushes & discs,non woven Polishing wheel,laser braze finishing wheel etc. We give you competitive price and never comprise to quality.

Q2: Can it be used on both manual tools and automated systems?

A: Yes, it is compatible with handheld grinders as well as robotic finishing systems commonly used in automotive assembly lines.

Q3: Is it suitable for aluminum and stainless steel?

A: Absolutely. The wheel works effectively on aluminum alloys, stainless steel, silicon bronze, and other metals commonly used in laser brazing.

Q4: How long does one wheel last?

A: Service life depends on application conditions, but thanks to the cotton-fiber construction and premium abrasives, it lasts significantly longer than conventional finishing wheels.

Q5: Can you provide product samples before bulk orders?

A: Yes, we can supply samples for testing to ensure the wheel meets your application requirements.

Notice

The safety performance of Nice Top grinding wheel is strictly tested and has clear safety operation instructions. However, it is still essential to install and use it properly and stick to the safety instruction. Each product is labeled with the MOS: Maximum Operating Speed. The actual operating speed can not exceed the maximum operating speed.

Moreover, Please also pay attention to the mechanical protection, wear the mask, safety glass and safety shoe. Pay attention to the ventilation of the workshop.

Due to variations in product models, specifications, and production lead times, prices may differ across different items. To receive an accurate quotation, we sincerely invite you to contact us with detailed product information, such as model number, dimensions, and estimated purchase quantity. Based on the details provided, we will offer a customized price quotation. We are also open to offering reasonable discounts depending on your order volume or specific requirements.

We warmly welcome your inquiries and are committed to working with you to find the most suitable and cost-effective solution.