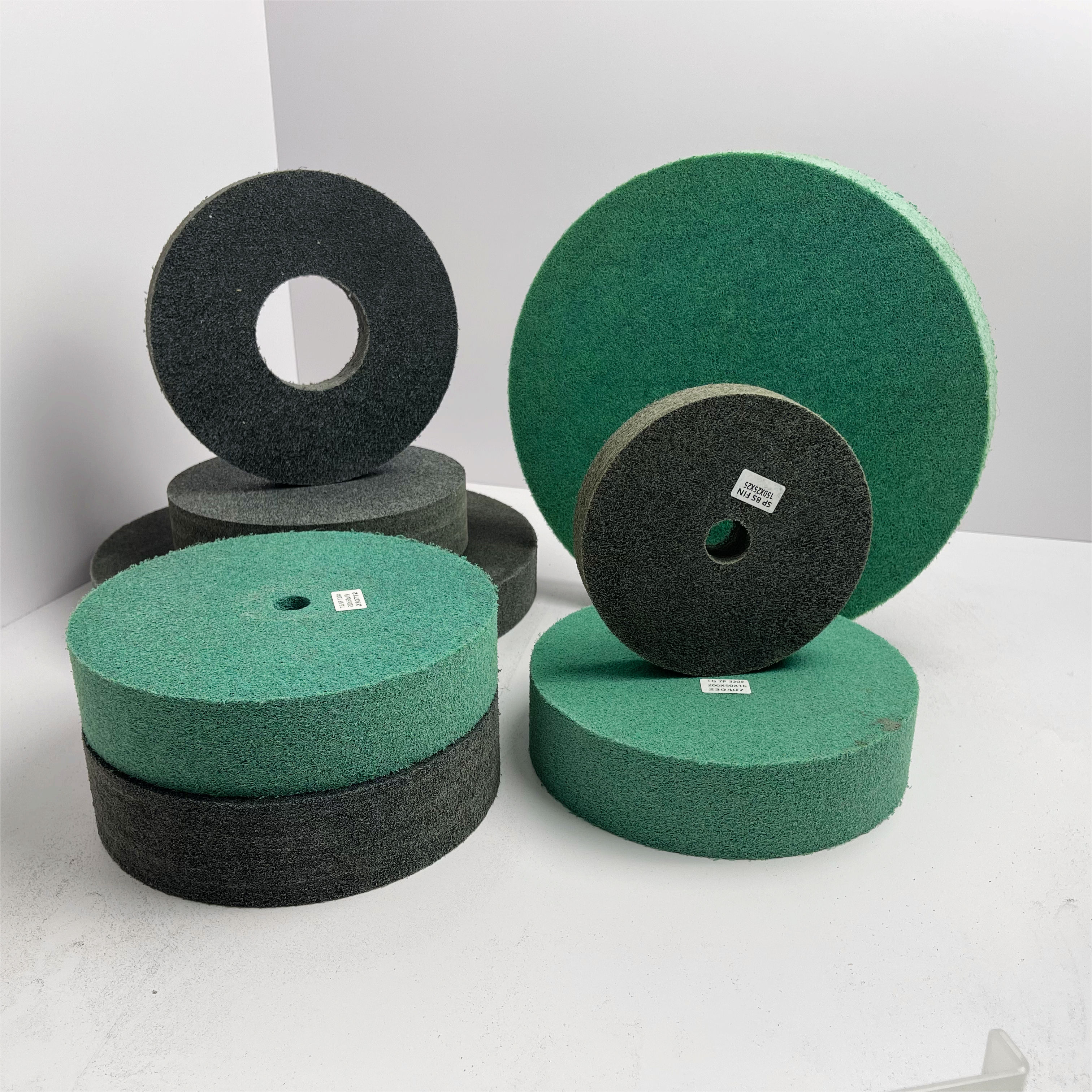

Views: 0 Author: Site Editor Publish Time: 2025-11-05 Origin: Nice Top Non Woven Polishing Wheels

Non Woven Polishing Wheels are engineered for high-performance industrial polishing and finishing. Their non woven fiber construction allows the wheel to adapt to irregular surfaces while maintaining uniform abrasive contact, resulting in high-quality finishes and reduced material damage.

Applications

Metalworking: Polishing and deburring stainless steel, aluminum, titanium, and other alloys. Ideal for removing weld seams, oxidation, and surface defects.

Automotive Industry: Smooths engine components, trims, and body panels efficiently, reducing rework and downtime.

Aerospace: Ensures consistent finishes on turbine blades, structural aluminum parts, and precision components.

Medical Tools: Provides low-heat polishing for surgical instruments, dental tools, and implants.

Wood and Composites: Removes imperfections and prepares surfaces for coatings and finishing.

Advantages

Versatile Use across metals, composites, plastics, and wood.

Durable Non Woven Fibers maintain abrasive performance.

Minimized Heat Generation protects sensitive surfaces.

Consistent and Predictable Finishes.

Economical due to long lifespan and reduced downtime.

Operational Benefits

Compatible with manual, bench, and automated systems, including CNC and robotic polishing equipment. Balanced construction reduces vibration, improves operator control, and increases workflow efficiency. Grit and density variations allow customization for fine polishing, deburring, or aggressive surface preparation.

Conclusion

Non Woven Polishing Wheels deliver reliable, high-quality finishes while enhancing industrial productivity. Their durability, versatility, and efficiency make them an essential tool for automotive, aerospace, medical, and metalworking applications.