| Type: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Density: | |||||||||

| Grade: | |||||||||

| Availability: | |||||||||

| Quantity: | |||||||||

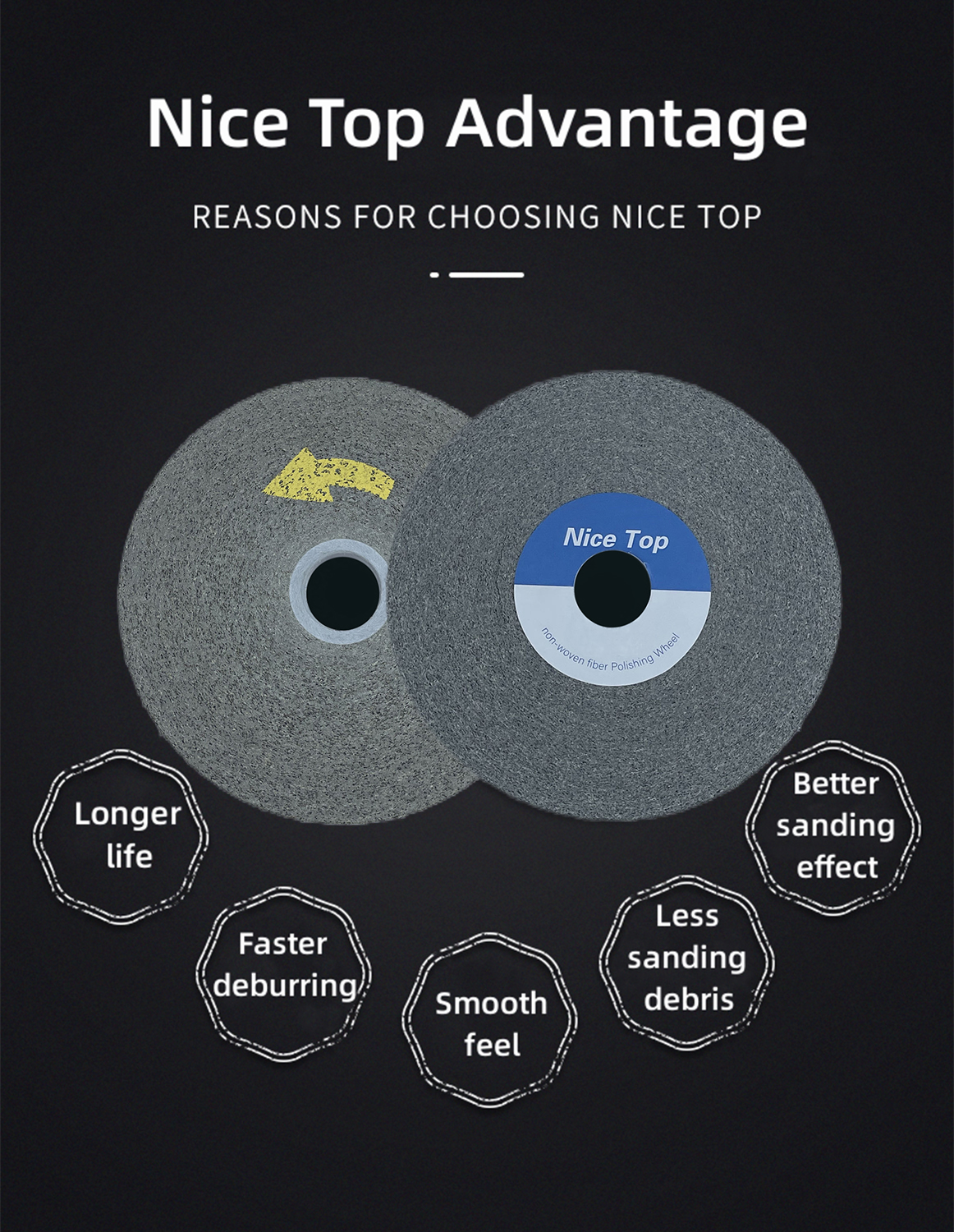

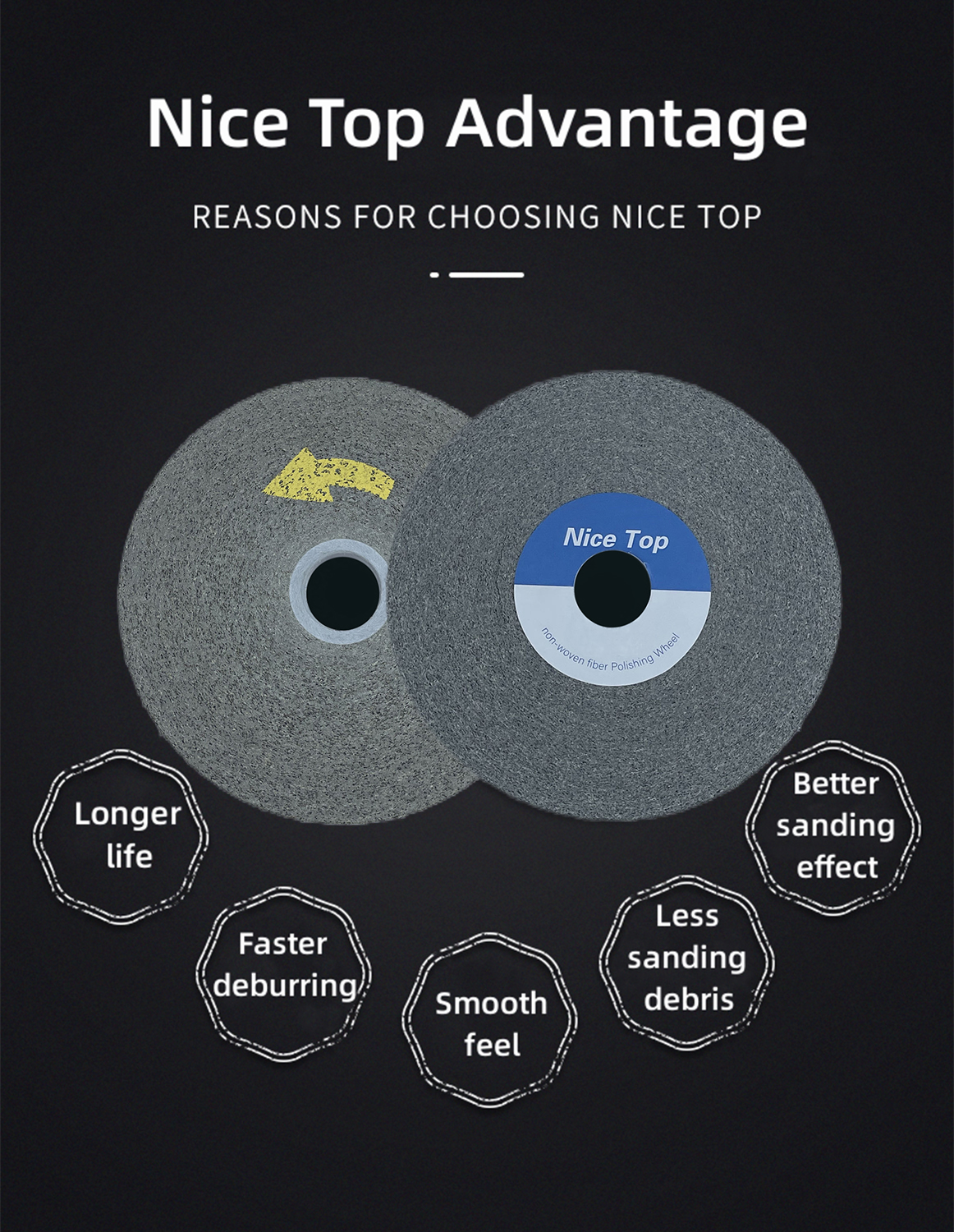

| Convolute Wheel for metal surface treatment, designed for clear and bright brushed metal applications. It provides consistent finishing performance with excellent durability and uniform surface quality. Ideal for deburring, cleaning, and polishing stainless steel, aluminum, and other metal materials.The convolute wheel stands as a cost-effective, high-performance alternative to established international brands like 3M and Norton Abrasives. | |||||||||

LD

Nice Top

LD Convolute Wheels for Deburring boast a hard, dense structure, suitable for fast processing of various metals, composites, and glass, including deburring, precision machining, and polishing, leaving a smooth, clean surface. Its versatility makes it perfect for deburring stamped or laser-cut parts and for precision machining after belt grinding.

The LD Convolute Wheel effectively removes burrs from metal parts, making it the ideal choice for deburring and polishing. Its lower operating temperature minimizes smearing, providing clean, uniform wear, ensuring smooth operation of the wheel, enabling operators to achieve professional surface finishes while reducing the pressure required on the workpiece.

the product offers a choice of silicon carbide or aluminum oxide abrasive minerals. Silicon carbide is suitable for low-pressure applications such as paint preparation and coatings, while aluminum oxide offers high cutting rates and long lifespan, suitable for finer workpiece treatment.

Product parameters

| Abrasive Material | Aluminum Oxide, Silicon Carbide |

| Application | Polishing, Deburring, Finishing |

| Brands | Nice Top |

| Overall Diameter | 12inch/304.8mm |

| Thickness | 1inch/25.4mm |

| Center Hole Diameter | 5inch/127mm |

| Grade | Coarse, Medium, Fine |

| Industries | Aerospace,Auto Manufacturer,Medical Equipment,Metalworking |

| Place of origin | China |

| Customized support | OEM, ODM |

Clean and Efficient

Delivers a deburring performance that is both efficient and clean, effectively removing light burrs without damaging or deforming the workpiece surface. The controlled cutting action preserves the material’s dimensions and finish, making it ideal for precision parts. This clean process reduces the need for rework or secondary polishing, improving productivity and surface consistency.

High Gloss

Creates a bright, uniform polishing effect that enhances product appearance and leaves the workpiece extremely smooth and reflective. The fine abrasive structure ensures consistent gloss, providing a professional, mirror-like finish. Perfect for decorative metals, stainless steel components, and applications demanding a high-end visual effect.

High-Density Scratches

Generates a tight, well-defined scratch pattern that enhances the visual appeal of the finished surface. The even texture reflects light consistently, creating a refined and professional look. Ideal for applications requiring both precision and aesthetic quality, such as stainless panels, appliances, and architectural metalwork.

Soft Adaptability

Made from flexible and resilient material, it conforms easily to complex shapes and contours, ensuring full surface contact and uniform finishing. This adaptability guarantees clean deburring and polishing without excessive material removal or edge damage, making it ideal for precision finishing in automotive, electronics, and aerospace industries.

Density

The density of the deburring disc determines its cutting strength and polishing performance. By adjusting density, the polishing thickness can be controlled to meet various deburring and finishing needs. Lower densities offer flexibility for delicate surfaces, while higher densities deliver faster material removal and longer life—making the wheel adaptable for different metals and alloys.

Mineral Grade

The Wheel uses silicon carbide (SiC) as the primary abrasive. Known for its sharpness and thermal stability, SiC ensures efficient and consistent cutting. Different mineral grades—fine to coarse—provide varying hardness and grit results: coarse grades remove heavy burrs, while finer grades deliver smooth, uniform finishes ready for coating or painting.

Diameters and Widths

Available in multiple diameters and thicknesses to suit different workpieces and machinery, typically from 100 mm to 400 mm. This range ensures compatibility with both manual and automated operations, supporting consistent finishing quality on parts of all sizes.

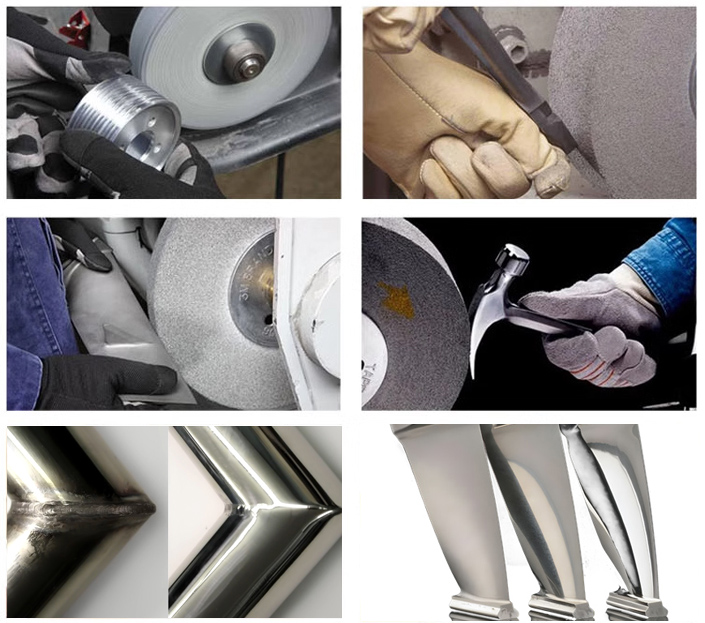

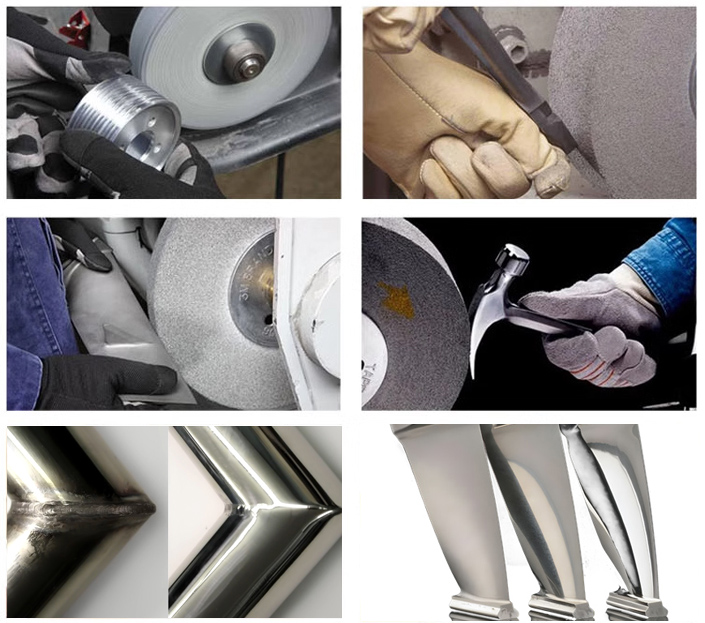

Automotive Manufacturing

Used for precision deburring and polishing of engine parts, brackets, and exhaust systems. The wheel removes sharp edges smoothly without affecting dimensions, enhancing both function and appearance.

Aerospace Industry

Ideal for high-strength materials such as titanium and Inconel. It removes micro-burrs and oxidation, ensuring clean, uniform surfaces that improve coating adhesion and part reliability under stress.

Medical Equipment

Applied to the cleaning and fine deburring of surgical tools, implants, and stainless components. Its consistent, contamination-free finish supports high hygiene standards and precision manufacturing.

Frequently Asked Questions (FAQ)

Q1: why should you buy from us not from other suppliers?

A: Nice Top has strong capability to design and produce world top convolute wheel, unitized wheel,bristle brushes & discs,non woven Polishing wheel,laser braze finishing wheel etc. We give you competitive price and never comprise to quality.

Q2: Can it be used on both manual tools and automated systems?

A: Yes, it is compatible with handheld grinders as well as robotic finishing systems commonly used in automotive assembly lines.

Q3: Is it suitable for aluminum and stainless steel?

A: Absolutely. The wheel works effectively on aluminum alloys, stainless steel, silicon bronze, and other metals commonly used in laser brazing.

Q4: How long does one wheel last?

A: Service life depends on application conditions, but thanks to the cotton-fiber construction and premium abrasives, it lasts significantly longer than conventional finishing wheels.

Q5: Can you provide product samples before bulk orders?

A: Yes, we can supply samples for testing to ensure the wheel meets your application requirements.

Notice

The safety performance of Nice Top grinding wheel is strictly tested and has clear safety operation instructions. However, it is still essential to install and use it properly and stick to the safety instruction. Each product is labeled with the MOS: Maximum Operating Speed . The actual operating speed can not exceed the maximum operating speed.

Moreover, Please also pay attention to the mechanical protection, wear the mask, safety glass and safety shoe. Pay attention to the ventilation of the workshop.

When operating convolute wheel, we should pay special attention to the arrowhead marked on the product, and the direction of the arrow is the rotation direction of the product. The product must be operated with the right direction.

Due to variations in product models, specifications, and production lead times, prices may differ across different items. To receive an accurate quotation, we sincerely invite you to contact us with detailed product information, such as model number, dimensions, and estimated purchase quantity. Based on the details provided, we will offer a customized price quotation. We are also open to offering reasonable discounts depending on your order volume or specific requirements.

We warmly welcome your inquiries and are committed to working with you to find the most suitable and cost-effective solution.

LD Convolute Wheels for Deburring boast a hard, dense structure, suitable for fast processing of various metals, composites, and glass, including deburring, precision machining, and polishing, leaving a smooth, clean surface. Its versatility makes it perfect for deburring stamped or laser-cut parts and for precision machining after belt grinding.

The LD Convolute Wheel effectively removes burrs from metal parts, making it the ideal choice for deburring and polishing. Its lower operating temperature minimizes smearing, providing clean, uniform wear, ensuring smooth operation of the wheel, enabling operators to achieve professional surface finishes while reducing the pressure required on the workpiece.

the product offers a choice of silicon carbide or aluminum oxide abrasive minerals. Silicon carbide is suitable for low-pressure applications such as paint preparation and coatings, while aluminum oxide offers high cutting rates and long lifespan, suitable for finer workpiece treatment.

Product parameters

| Abrasive Material | Aluminum Oxide, Silicon Carbide |

| Application | Polishing, Deburring, Finishing |

| Brands | Nice Top |

| Overall Diameter | 12inch/304.8mm |

| Thickness | 1inch/25.4mm |

| Center Hole Diameter | 5inch/127mm |

| Grade | Coarse, Medium, Fine |

| Industries | Aerospace,Auto Manufacturer,Medical Equipment,Metalworking |

| Place of origin | China |

| Customized support | OEM, ODM |

Clean and Efficient

Delivers a deburring performance that is both efficient and clean, effectively removing light burrs without damaging or deforming the workpiece surface. The controlled cutting action preserves the material’s dimensions and finish, making it ideal for precision parts. This clean process reduces the need for rework or secondary polishing, improving productivity and surface consistency.

High Gloss

Creates a bright, uniform polishing effect that enhances product appearance and leaves the workpiece extremely smooth and reflective. The fine abrasive structure ensures consistent gloss, providing a professional, mirror-like finish. Perfect for decorative metals, stainless steel components, and applications demanding a high-end visual effect.

High-Density Scratches

Generates a tight, well-defined scratch pattern that enhances the visual appeal of the finished surface. The even texture reflects light consistently, creating a refined and professional look. Ideal for applications requiring both precision and aesthetic quality, such as stainless panels, appliances, and architectural metalwork.

Soft Adaptability

Made from flexible and resilient material, it conforms easily to complex shapes and contours, ensuring full surface contact and uniform finishing. This adaptability guarantees clean deburring and polishing without excessive material removal or edge damage, making it ideal for precision finishing in automotive, electronics, and aerospace industries.

Density

The density of the deburring disc determines its cutting strength and polishing performance. By adjusting density, the polishing thickness can be controlled to meet various deburring and finishing needs. Lower densities offer flexibility for delicate surfaces, while higher densities deliver faster material removal and longer life—making the wheel adaptable for different metals and alloys.

Mineral Grade

The Wheel uses silicon carbide (SiC) as the primary abrasive. Known for its sharpness and thermal stability, SiC ensures efficient and consistent cutting. Different mineral grades—fine to coarse—provide varying hardness and grit results: coarse grades remove heavy burrs, while finer grades deliver smooth, uniform finishes ready for coating or painting.

Diameters and Widths

Available in multiple diameters and thicknesses to suit different workpieces and machinery, typically from 100 mm to 400 mm. This range ensures compatibility with both manual and automated operations, supporting consistent finishing quality on parts of all sizes.

Automotive Manufacturing

Used for precision deburring and polishing of engine parts, brackets, and exhaust systems. The wheel removes sharp edges smoothly without affecting dimensions, enhancing both function and appearance.

Aerospace Industry

Ideal for high-strength materials such as titanium and Inconel. It removes micro-burrs and oxidation, ensuring clean, uniform surfaces that improve coating adhesion and part reliability under stress.

Medical Equipment

Applied to the cleaning and fine deburring of surgical tools, implants, and stainless components. Its consistent, contamination-free finish supports high hygiene standards and precision manufacturing.

Frequently Asked Questions (FAQ)

Q1: why should you buy from us not from other suppliers?

A: Nice Top has strong capability to design and produce world top convolute wheel, unitized wheel,bristle brushes & discs,non woven Polishing wheel,laser braze finishing wheel etc. We give you competitive price and never comprise to quality.

Q2: Can it be used on both manual tools and automated systems?

A: Yes, it is compatible with handheld grinders as well as robotic finishing systems commonly used in automotive assembly lines.

Q3: Is it suitable for aluminum and stainless steel?

A: Absolutely. The wheel works effectively on aluminum alloys, stainless steel, silicon bronze, and other metals commonly used in laser brazing.

Q4: How long does one wheel last?

A: Service life depends on application conditions, but thanks to the cotton-fiber construction and premium abrasives, it lasts significantly longer than conventional finishing wheels.

Q5: Can you provide product samples before bulk orders?

A: Yes, we can supply samples for testing to ensure the wheel meets your application requirements.

Notice

The safety performance of Nice Top grinding wheel is strictly tested and has clear safety operation instructions. However, it is still essential to install and use it properly and stick to the safety instruction. Each product is labeled with the MOS: Maximum Operating Speed . The actual operating speed can not exceed the maximum operating speed.

Moreover, Please also pay attention to the mechanical protection, wear the mask, safety glass and safety shoe. Pay attention to the ventilation of the workshop.

When operating convolute wheel, we should pay special attention to the arrowhead marked on the product, and the direction of the arrow is the rotation direction of the product. The product must be operated with the right direction.

Due to variations in product models, specifications, and production lead times, prices may differ across different items. To receive an accurate quotation, we sincerely invite you to contact us with detailed product information, such as model number, dimensions, and estimated purchase quantity. Based on the details provided, we will offer a customized price quotation. We are also open to offering reasonable discounts depending on your order volume or specific requirements.

We warmly welcome your inquiries and are committed to working with you to find the most suitable and cost-effective solution.