| Type: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Density: | |||||||||

| Grade: | |||||||||

| Availability: | |||||||||

| Quantity: | |||||||||

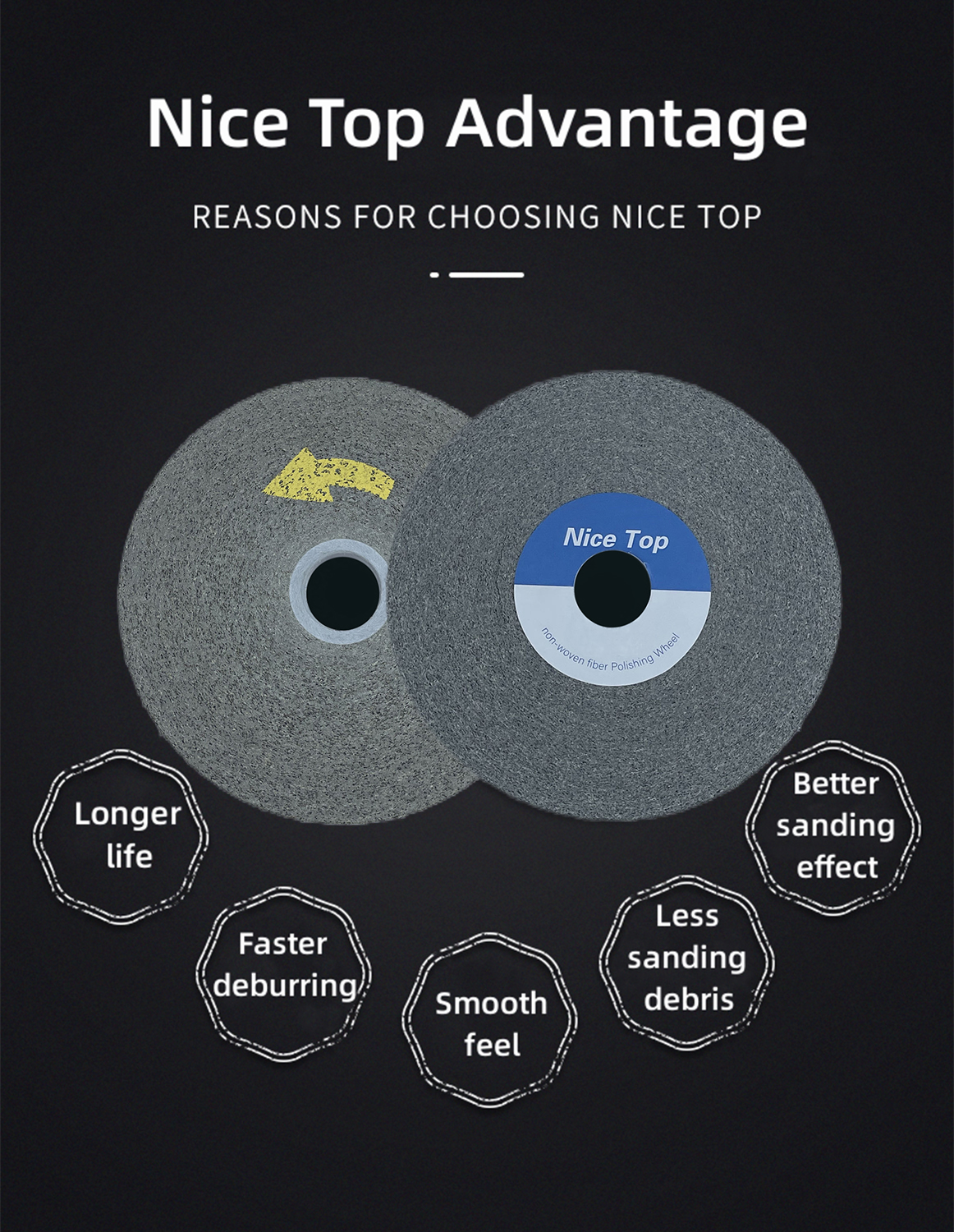

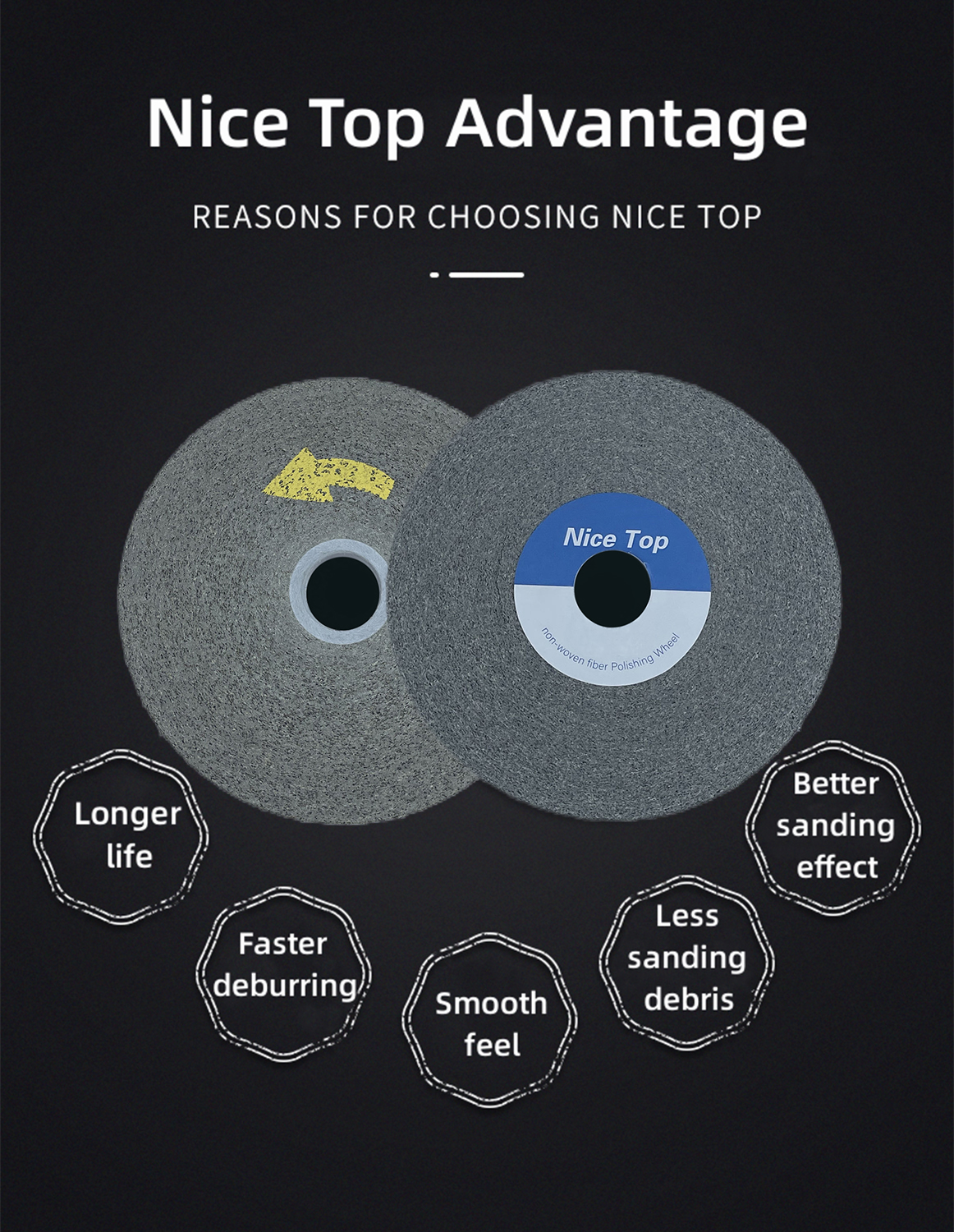

| EXT deburring convolute wheels can quickly remove burrs, burrs and rust from the workpiece surface, providing a smooth surface treatment. They can complete grinding tasks in a shorter time and improve production efficiency.The convolute wheel stands as a cost-effective, high-performance alternative to established international brands like 3M and Norton Abrasives. | |||||||||

EXT

Nice Top

The Deburring Convolute Wheel is a high-performance, multi-purpose finishing tool designed to deliver exceptional results across a wide range of industrial applications. Comparable in performance to the Scotch-Brite™ Deburring Wheel, it features medium hardness and strength, making it ideal for deburring, edge radiusing, blending, polishing, and final finishing.

Whether you are dealing with sharp edges, stubborn burrs, or irregular profiles, this wheel excels at creating a smooth, consistent finish without compromising the part’s geometry. Its non-woven 3D construction ensures a long service life, even under demanding conditions, and allows it to maintain its cutting power while providing a controlled, uniform surface finish.

Product Parameters

| Abrasive Material | Aluminum Oxide, Silicon Carbide |

| Application | Polishing, Deburring, Finishing |

| Brands | Nice Top |

| Overall Diameter | 6inch/152.4mm |

| Thickness | 0.25inch/6.35mm |

| Center Hole Diameter | 1inch/25.4mm |

| Grade | Coarse, Medium, Fine |

| Industries | Aerospace,Auto Manufacturer,Medical Equipment,Metalworking |

| Place of origin | China |

| Customized support | OEM, ODM |

Key Features & Benefits

Comparable to Scotch-Brite

Delivers performance equal to top brands like Scotch-Brite, while offering greater flexibility and cost savings. Provides consistent cutting action and high-quality finishes—an ideal choice for those seeking reliable results at a better value.

Medium Hardness, Maximum Versatility

Balances durability with flexibility, handling both light and medium deburring tasks. Maintains shape while adapting to irregular surfaces, ensuring smooth, even finishes on flat and complex parts alike.

Precision on Complex Materials

Easily trimmed and shaped for custom applications. Ideal for detailed work on metal alloys, plastics, and composites that require fine edge control and consistent surface texture.

Long-Lasting, Consistent Performance

3D non-woven construction resists loading and heat buildup, maintaining steady performance over long use. Ensures uniform finishes and extended tool life in demanding operations.

Heat & Load Resistance

Open structure allows cooling airflow, minimizing heat, discoloration, and deformation. Ideal for temperature-sensitive materials like plastics, titanium, and coated metals.

Multi-Material Compatibility

Performs effectively on stainless steel, aluminum, titanium, carbon fiber, and plastics. Suitable for deburring, surface conditioning, and polishing across multiple industries.

Applications

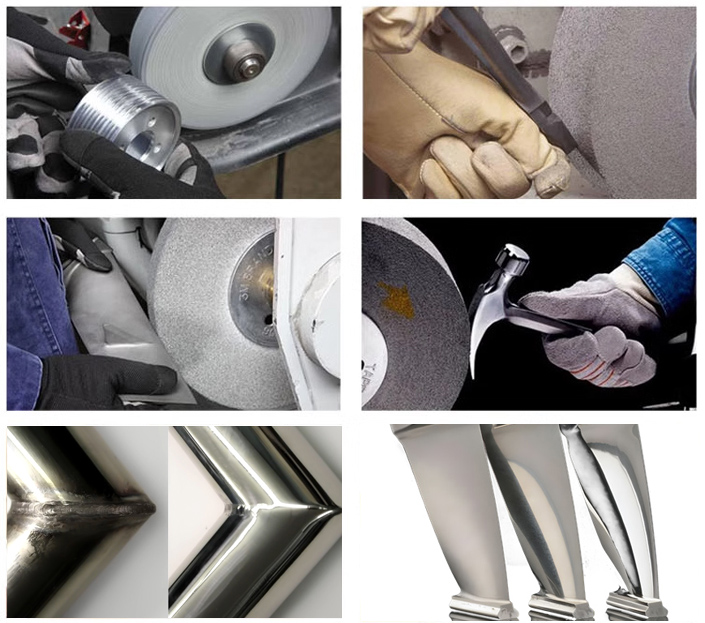

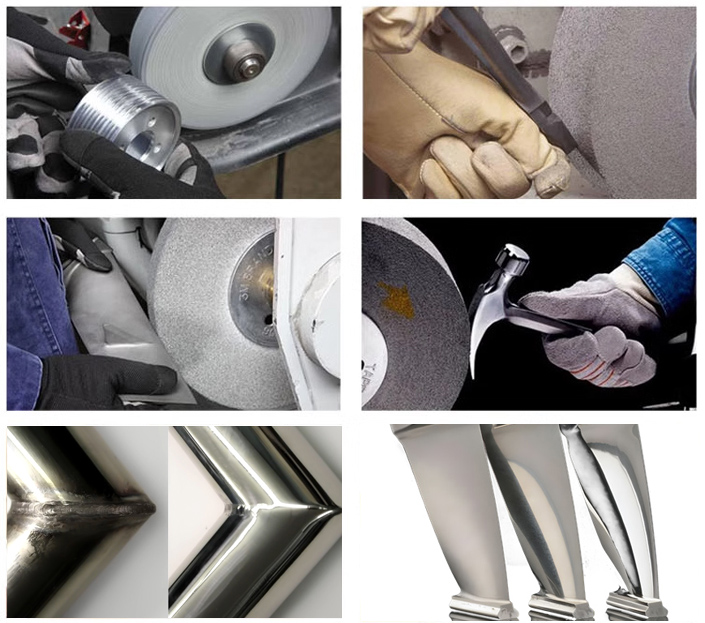

Deburring and finishing machined parts

Quickly removes burrs, sharp edges, and surface flaws, improving both appearance and functionality. Ideal for precision parts where smooth edges and consistent quality are essential.

Creating controlled edge radii

Delivers accurate, repeatable edge rounding to maintain tight tolerances and prevent stress points. Ensures uniform results on complex geometries for aerospace, electronics, and precision machinery.

Surface preparation before painting, welding, or coating

Removes rust, oxidation, and contaminants, creating a clean, even surface for strong coating adhesion. Perfect for fabrication, automotive, and industrial pre-treatment applications.

Polishing plastic or composite parts

Produces smooth, uniform finishes without heat damage or smearing. Excellent for finishing plastic housings, composite panels, and parts in electronics or medical devices.

Final finishing for medical, aerospace, and automotive components

Provides the high-quality, consistent finishes required for critical components like surgical tools, turbine blades, and metal trims. Ensures both performance and professional appearance.

Frequently Asked Questions (FAQ)

Q1: why should you buy from us not from other suppliers?

A: Nice Top has strong capability to design and produce world top convolute wheel, unitized wheel,bristle brushes & discs,non woven Polishing wheel,laser braze finishing wheel etc. We give you competitive price and never comprise to quality.

Q2: Can it be used on both manual tools and automated systems?

A: Yes, it is compatible with handheld grinders as well as robotic finishing systems commonly used in automotive assembly lines.

Q3: Is it suitable for aluminum and stainless steel?

A: Absolutely. The wheel works effectively on aluminum alloys, stainless steel, silicon bronze, and other metals commonly used in laser brazing.

Q4: How long does one wheel last?

A: Service life depends on application conditions, but thanks to the cotton-fiber construction and premium abrasives, it lasts significantly longer than conventional finishing wheels.

Q5: Can you provide product samples before bulk orders?

A: Yes, we can supply samples for testing to ensure the wheel meets your application requirements.

Notice

The safety performance of Nice Top grinding wheel is strictly tested and has clear safety operation instructions. However, it is still essential to install and use it properly and stick to the safety instruction. Each product is labeled with the MOS: Maximum Operating Speed. The actual operating speed can not exceed the maximum operating speed.

Moreover, Please also pay attention to the mechanical protection, wear the mask, safety glass and safety shoe. Pay attention to the ventilation of the workshop.

When operating convolute wheel, we should pay special attention to the arrowhead marked on the product, and the direction of the arrow is the rotation direction of the product. The product must be operated with the right direction.

Whether you're in high-volume manufacturing or custom fabrication, our Convolute Wheels help you improve efficiency, surface quality, and process consistency. They're trusted by professionals across industries to deliver the perfect balance of performance, precision, and longevity.

Contact us today to discuss your specific needs, request samples, or get a tailored quotation—we’re here to support your finishing success.

The Deburring Convolute Wheel is a high-performance, multi-purpose finishing tool designed to deliver exceptional results across a wide range of industrial applications. Comparable in performance to the Scotch-Brite™ Deburring Wheel, it features medium hardness and strength, making it ideal for deburring, edge radiusing, blending, polishing, and final finishing.

Whether you are dealing with sharp edges, stubborn burrs, or irregular profiles, this wheel excels at creating a smooth, consistent finish without compromising the part’s geometry. Its non-woven 3D construction ensures a long service life, even under demanding conditions, and allows it to maintain its cutting power while providing a controlled, uniform surface finish.

Product Parameters

| Abrasive Material | Aluminum Oxide, Silicon Carbide |

| Application | Polishing, Deburring, Finishing |

| Brands | Nice Top |

| Overall Diameter | 6inch/152.4mm |

| Thickness | 0.25inch/6.35mm |

| Center Hole Diameter | 1inch/25.4mm |

| Grade | Coarse, Medium, Fine |

| Industries | Aerospace,Auto Manufacturer,Medical Equipment,Metalworking |

| Place of origin | China |

| Customized support | OEM, ODM |

Key Features & Benefits

Comparable to Scotch-Brite

Delivers performance equal to top brands like Scotch-Brite, while offering greater flexibility and cost savings. Provides consistent cutting action and high-quality finishes—an ideal choice for those seeking reliable results at a better value.

Medium Hardness, Maximum Versatility

Balances durability with flexibility, handling both light and medium deburring tasks. Maintains shape while adapting to irregular surfaces, ensuring smooth, even finishes on flat and complex parts alike.

Precision on Complex Materials

Easily trimmed and shaped for custom applications. Ideal for detailed work on metal alloys, plastics, and composites that require fine edge control and consistent surface texture.

Long-Lasting, Consistent Performance

3D non-woven construction resists loading and heat buildup, maintaining steady performance over long use. Ensures uniform finishes and extended tool life in demanding operations.

Heat & Load Resistance

Open structure allows cooling airflow, minimizing heat, discoloration, and deformation. Ideal for temperature-sensitive materials like plastics, titanium, and coated metals.

Multi-Material Compatibility

Performs effectively on stainless steel, aluminum, titanium, carbon fiber, and plastics. Suitable for deburring, surface conditioning, and polishing across multiple industries.

Applications

Deburring and finishing machined parts

Quickly removes burrs, sharp edges, and surface flaws, improving both appearance and functionality. Ideal for precision parts where smooth edges and consistent quality are essential.

Creating controlled edge radii

Delivers accurate, repeatable edge rounding to maintain tight tolerances and prevent stress points. Ensures uniform results on complex geometries for aerospace, electronics, and precision machinery.

Surface preparation before painting, welding, or coating

Removes rust, oxidation, and contaminants, creating a clean, even surface for strong coating adhesion. Perfect for fabrication, automotive, and industrial pre-treatment applications.

Polishing plastic or composite parts

Produces smooth, uniform finishes without heat damage or smearing. Excellent for finishing plastic housings, composite panels, and parts in electronics or medical devices.

Final finishing for medical, aerospace, and automotive components

Provides the high-quality, consistent finishes required for critical components like surgical tools, turbine blades, and metal trims. Ensures both performance and professional appearance.

Frequently Asked Questions (FAQ)

Q1: why should you buy from us not from other suppliers?

A: Nice Top has strong capability to design and produce world top convolute wheel, unitized wheel,bristle brushes & discs,non woven Polishing wheel,laser braze finishing wheel etc. We give you competitive price and never comprise to quality.

Q2: Can it be used on both manual tools and automated systems?

A: Yes, it is compatible with handheld grinders as well as robotic finishing systems commonly used in automotive assembly lines.

Q3: Is it suitable for aluminum and stainless steel?

A: Absolutely. The wheel works effectively on aluminum alloys, stainless steel, silicon bronze, and other metals commonly used in laser brazing.

Q4: How long does one wheel last?

A: Service life depends on application conditions, but thanks to the cotton-fiber construction and premium abrasives, it lasts significantly longer than conventional finishing wheels.

Q5: Can you provide product samples before bulk orders?

A: Yes, we can supply samples for testing to ensure the wheel meets your application requirements.

Notice

The safety performance of Nice Top grinding wheel is strictly tested and has clear safety operation instructions. However, it is still essential to install and use it properly and stick to the safety instruction. Each product is labeled with the MOS: Maximum Operating Speed. The actual operating speed can not exceed the maximum operating speed.

Moreover, Please also pay attention to the mechanical protection, wear the mask, safety glass and safety shoe. Pay attention to the ventilation of the workshop.

When operating convolute wheel, we should pay special attention to the arrowhead marked on the product, and the direction of the arrow is the rotation direction of the product. The product must be operated with the right direction.

Whether you're in high-volume manufacturing or custom fabrication, our Convolute Wheels help you improve efficiency, surface quality, and process consistency. They're trusted by professionals across industries to deliver the perfect balance of performance, precision, and longevity.

Contact us today to discuss your specific needs, request samples, or get a tailored quotation—we’re here to support your finishing success.