| Type: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Density: | |||||||||

| Grade: | |||||||||

| Availability: | |||||||||

| Quantity: | |||||||||

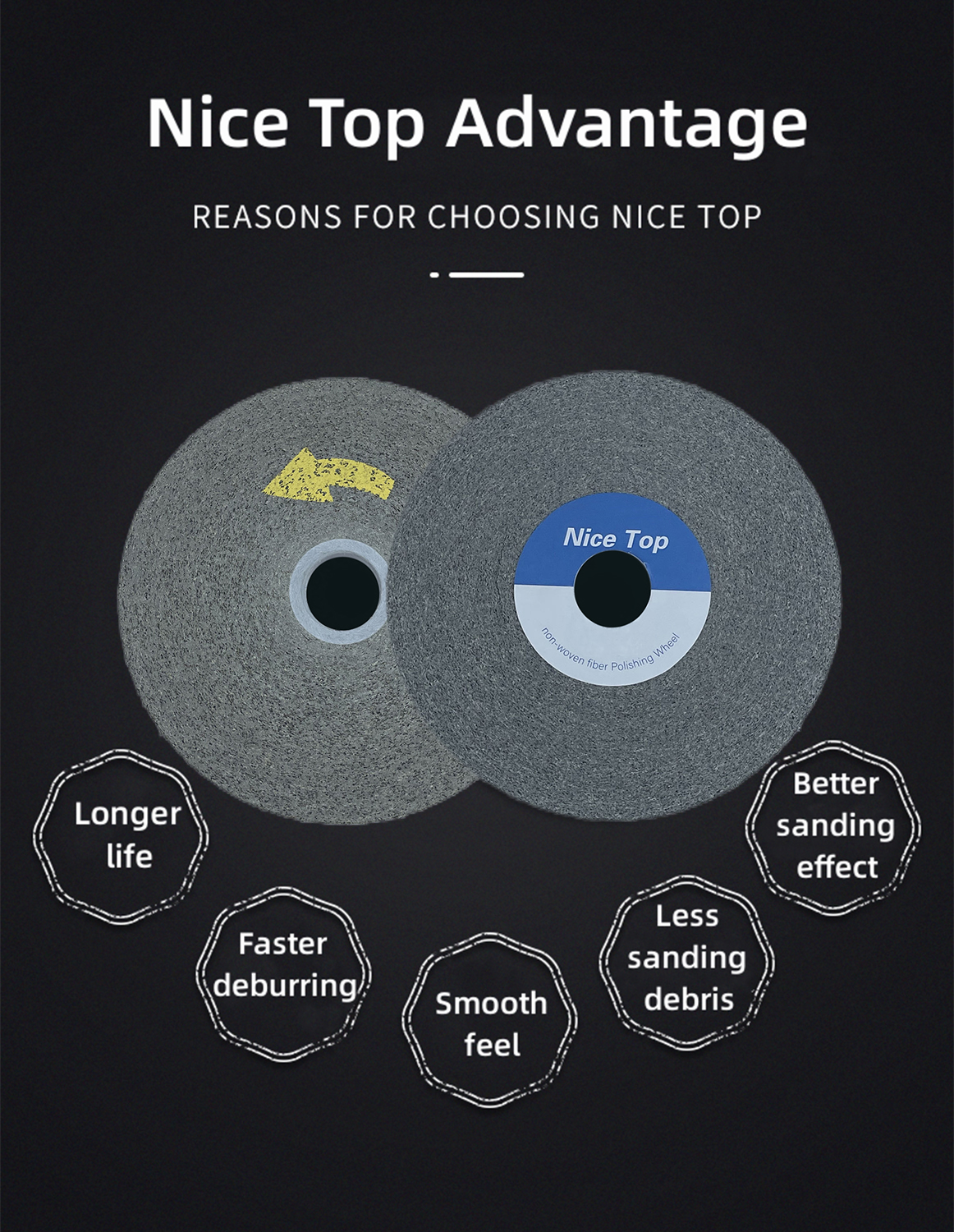

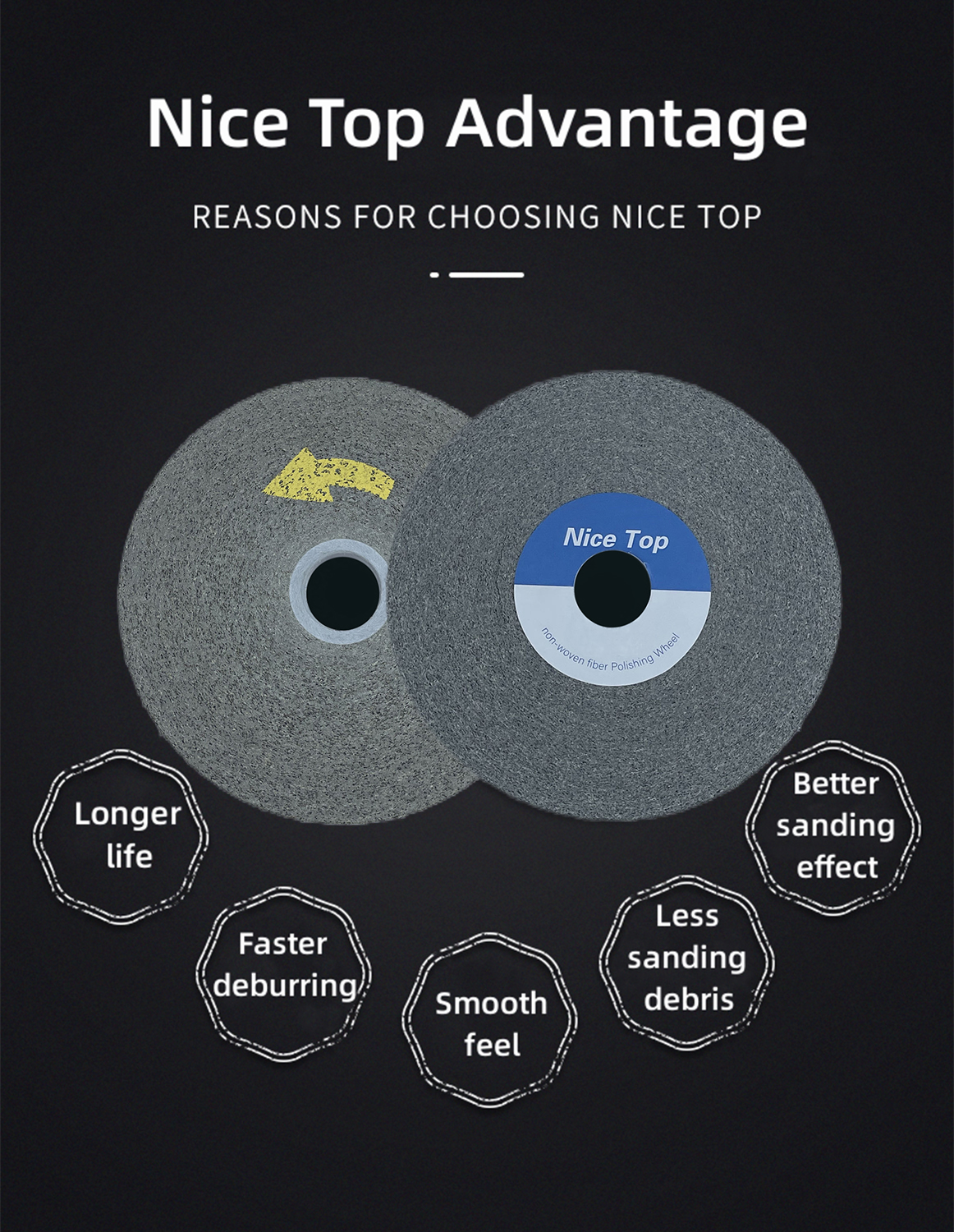

| The Deburring Convolute Wheel offers affordable pricing and order options while delivering satisfactory performance. It is suitable for light to moderate deburring tasks, as well as cleaning and finishing purposes.The convolute wheel stands as a cost-effective, high-performance alternative to established international brands like 3M and Norton Abrasives. | |||||||||

LD

Nice Top

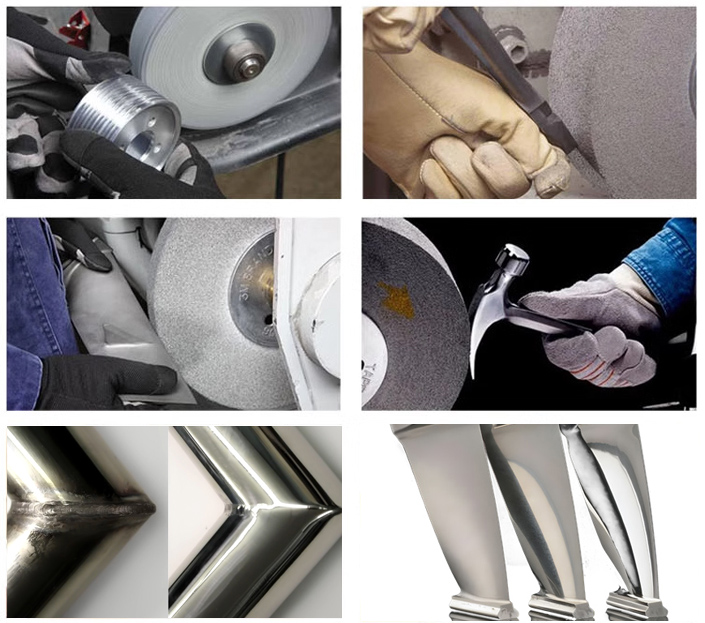

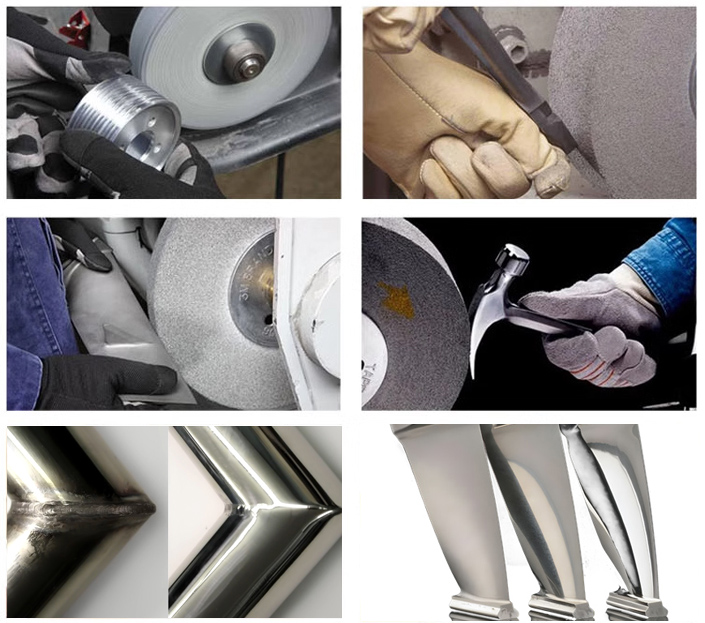

Abrasive tools called deburring wheels are made expressly to process glass, metals, and composites quickly. They are great for deburring, finishing, and polishing, leaving surfaces smooth and clean, thanks to their dense and sturdy construction. For industrial applications, LD deburring convolute wheels are the best option because of their low working temperature, consistent wear, and compatibility with heat-sensitive materials.

Crafted with premium nonwoven nylon fibers and premium abrasives such as silicon carbide and aluminum oxide, these wheels feature a dense yet resilient structure. The integrated design minimizes heat buildup, ensuring consistent abrasive performance and professional results throughout their lifespan. Easy installation and replacement for hassle-free use.

| Abrasive Material | Aluminum Oxide, Silicon Carbide |

| Application | Polishing, Deburring, Finishing |

| Brands | Nice Top |

| Overall Diameter | 12inch/304.8mm |

| Thickness | 2inch/50.8mm |

| Center Hole Diameter | 5inch/127mm |

| Grade | Coarse, Medium, Fine |

| Industries | Aerospace,Auto Manufacturer,Medical Equipment,Metalworking |

| Place of origin | China |

| Customized support | OEM, ODM |

The hard and dense structure of the deburring wheels enables them to perform high-load processing operations. Superior non-woven materials offer the required toughness, guaranteeing even abrasive dispersion and ongoing exposure, hence increasing the wheel's lifespan.

Glass, composites, and metals are among the materials that deburring wheels can be used to process. They offer a broad range of industrial application solutions and excel in deburring stamped or laser-cut parts and finishing after belt grinding.

EXL deburring convoluted wheels function at a lower temperature, which lessens heat-induced material damage or deformation. While minimising the amount of pressure applied to the workpiece, the homogeneous wear characteristics guarantee uniformity and excellent polishing of the workpiece surfaces.

Debourring wheels are designed with the comfort of the operator in mind, which reduces fatigue during extended operations. The smooth-running feature lessens vibration, resulting in surface treatment outcomes that are finer and more expert.

Burring wheels provide options for silicon carbide and aluminum oxide abrasives based on application requirements. Aluminum oxide is best suited for more exact workpiece processing due to its extended lifespan and high cutting rate, whereas silicon carbide works well in low-pressure applications like paint preparation and finishing.

EXL deburring wheels are a great option for automated and robotic deburring applications because of its durability and consistent wear characteristics. They guarantee excellent processing quality while increasing production consistency and efficiency.

Frequently Asked Questions (FAQ)

Q1: why should you buy from us not from other suppliers?

A: Nice Top has strong capability to design and produce world top convolute wheel, unitized wheel,bristle brushes & discs,non woven Polishing wheel,laser braze finishing wheel etc. We give you competitive price and never comprise to quality.

Q2: Can it be used on both manual tools and automated systems?

A: Yes, it is compatible with handheld grinders as well as robotic finishing systems commonly used in automotive assembly lines.

Q3: Is it suitable for aluminum and stainless steel?

A: Absolutely. The wheel works effectively on aluminum alloys, stainless steel, silicon bronze, and other metals commonly used in laser brazing.

Q4: How long does one wheel last?

A: Service life depends on application conditions, but thanks to the cotton-fiber construction and premium abrasives, it lasts significantly longer than conventional finishing wheels.

Q5: Can you provide product samples before bulk orders?

A: Yes, we can supply samples for testing to ensure the wheel meets your application requirements.

Suggestions

Select the appropriate specification and granularity

Select the appropriate convolute wheel specification and granularity based on the workpiece material and the desired surface treatment effect. The coarser grit is suitable for quick deburring and trimming, while the finer grit is suitable for detailed polishing and surfaces requiring a higher finish.

Use the correct grinding wheel type

Choose the appropriate convolute wheel type based on specific application needs. Different types of convolute wheels have different grinding characteristics and application ranges, such as hardness, softness and selection of grinding materials.

Maintain proper grinding pressure

When using the convolute wheel, it is important to maintain proper grinding pressure. Too much pressure may cause excessive wear or excessive heat build-up, while too little pressure may not achieve the desired grinding effect.

Control grinding speed

Controlling grinding speed can help achieve consistent grinding results. Speeds that are too fast may result in thermal damage to the surface or uneven grinding, while speeds that are too slow may result in poor grinding results.

Clean and maintain the grinding wheel regularly

Cleaning and maintaining the convolute wheel regularly can extend its service life and maintain good grinding results. Remove sand and impurities from the grinding wheel and ensure that the surface of the grinding wheel remains flat and even.

Use personal protective equipment

When using the convolute wheel, always wear appropriate personal protective equipment such as safety glasses, gloves, and a protective mask. This protects your eyes, hands, and face from dust and debris created during the grinding process.

Frequently Asked Questions (FAQ)

Q1: why should you buy from us not from other suppliers?

A: Nice Top has strong capability to design and produce world top convolute wheel, unitized wheel,bristle brushes & discs,non woven Polishing wheel,laser braze finishing wheel etc. We give you competitive price and never comprise to quality.

Q2: Can it be used on both manual tools and automated systems?

A: Yes, it is compatible with handheld grinders as well as robotic finishing systems commonly used in automotive assembly lines.

Q3: Is it suitable for aluminum and stainless steel?

A: Absolutely. The wheel works effectively on aluminum alloys, stainless steel, silicon bronze, and other metals commonly used in laser brazing.

Q4: How long does one wheel last?

A: Service life depends on application conditions, but thanks to the cotton-fiber construction and premium abrasives, it lasts significantly longer than conventional finishing wheels.

Q5: Can you provide product samples before bulk orders?

A: Yes, we can supply samples for testing to ensure the wheel meets your application requirements.

Notice

The safety performance of Nice Top grinding wheel is strictly tested and has clear safety operation instructions. However, it is still essential to install and use it properly and stick to the safety instruction. Each product is labeled with the MOS: Maximum Operating Speed. The actual operating speed can not exceed the maximum operating speed.

Moreover, Please also pay attention to the mechanical protection, wear the mask, safety glass and safety shoe. Pay attention to the ventilation of the workshop.

Due to variations in product models, specifications, and production lead times, prices may differ across different items. To receive an accurate quotation, we sincerely invite you to contact us with detailed product information, such as model number, dimensions, and estimated purchase quantity. Based on the details provided, we will offer a customized price quotation. We are also open to offering reasonable discounts depending on your order volume or specific requirements.

We warmly welcome your inquiries and are committed to working with you to find the most suitable and cost-effective solution.

Abrasive tools called deburring wheels are made expressly to process glass, metals, and composites quickly. They are great for deburring, finishing, and polishing, leaving surfaces smooth and clean, thanks to their dense and sturdy construction. For industrial applications, LD deburring convolute wheels are the best option because of their low working temperature, consistent wear, and compatibility with heat-sensitive materials.

Crafted with premium nonwoven nylon fibers and premium abrasives such as silicon carbide and aluminum oxide, these wheels feature a dense yet resilient structure. The integrated design minimizes heat buildup, ensuring consistent abrasive performance and professional results throughout their lifespan. Easy installation and replacement for hassle-free use.

| Abrasive Material | Aluminum Oxide, Silicon Carbide |

| Application | Polishing, Deburring, Finishing |

| Brands | Nice Top |

| Overall Diameter | 12inch/304.8mm |

| Thickness | 2inch/50.8mm |

| Center Hole Diameter | 5inch/127mm |

| Grade | Coarse, Medium, Fine |

| Industries | Aerospace,Auto Manufacturer,Medical Equipment,Metalworking |

| Place of origin | China |

| Customized support | OEM, ODM |

The hard and dense structure of the deburring wheels enables them to perform high-load processing operations. Superior non-woven materials offer the required toughness, guaranteeing even abrasive dispersion and ongoing exposure, hence increasing the wheel's lifespan.

Glass, composites, and metals are among the materials that deburring wheels can be used to process. They offer a broad range of industrial application solutions and excel in deburring stamped or laser-cut parts and finishing after belt grinding.

EXL deburring convoluted wheels function at a lower temperature, which lessens heat-induced material damage or deformation. While minimising the amount of pressure applied to the workpiece, the homogeneous wear characteristics guarantee uniformity and excellent polishing of the workpiece surfaces.

Debourring wheels are designed with the comfort of the operator in mind, which reduces fatigue during extended operations. The smooth-running feature lessens vibration, resulting in surface treatment outcomes that are finer and more expert.

Burring wheels provide options for silicon carbide and aluminum oxide abrasives based on application requirements. Aluminum oxide is best suited for more exact workpiece processing due to its extended lifespan and high cutting rate, whereas silicon carbide works well in low-pressure applications like paint preparation and finishing.

EXL deburring wheels are a great option for automated and robotic deburring applications because of its durability and consistent wear characteristics. They guarantee excellent processing quality while increasing production consistency and efficiency.

Frequently Asked Questions (FAQ)

Q1: why should you buy from us not from other suppliers?

A: Nice Top has strong capability to design and produce world top convolute wheel, unitized wheel,bristle brushes & discs,non woven Polishing wheel,laser braze finishing wheel etc. We give you competitive price and never comprise to quality.

Q2: Can it be used on both manual tools and automated systems?

A: Yes, it is compatible with handheld grinders as well as robotic finishing systems commonly used in automotive assembly lines.

Q3: Is it suitable for aluminum and stainless steel?

A: Absolutely. The wheel works effectively on aluminum alloys, stainless steel, silicon bronze, and other metals commonly used in laser brazing.

Q4: How long does one wheel last?

A: Service life depends on application conditions, but thanks to the cotton-fiber construction and premium abrasives, it lasts significantly longer than conventional finishing wheels.

Q5: Can you provide product samples before bulk orders?

A: Yes, we can supply samples for testing to ensure the wheel meets your application requirements.

Suggestions

Select the appropriate specification and granularity

Select the appropriate convolute wheel specification and granularity based on the workpiece material and the desired surface treatment effect. The coarser grit is suitable for quick deburring and trimming, while the finer grit is suitable for detailed polishing and surfaces requiring a higher finish.

Use the correct grinding wheel type

Choose the appropriate convolute wheel type based on specific application needs. Different types of convolute wheels have different grinding characteristics and application ranges, such as hardness, softness and selection of grinding materials.

Maintain proper grinding pressure

When using the convolute wheel, it is important to maintain proper grinding pressure. Too much pressure may cause excessive wear or excessive heat build-up, while too little pressure may not achieve the desired grinding effect.

Control grinding speed

Controlling grinding speed can help achieve consistent grinding results. Speeds that are too fast may result in thermal damage to the surface or uneven grinding, while speeds that are too slow may result in poor grinding results.

Clean and maintain the grinding wheel regularly

Cleaning and maintaining the convolute wheel regularly can extend its service life and maintain good grinding results. Remove sand and impurities from the grinding wheel and ensure that the surface of the grinding wheel remains flat and even.

Use personal protective equipment

When using the convolute wheel, always wear appropriate personal protective equipment such as safety glasses, gloves, and a protective mask. This protects your eyes, hands, and face from dust and debris created during the grinding process.

Frequently Asked Questions (FAQ)

Q1: why should you buy from us not from other suppliers?

A: Nice Top has strong capability to design and produce world top convolute wheel, unitized wheel,bristle brushes & discs,non woven Polishing wheel,laser braze finishing wheel etc. We give you competitive price and never comprise to quality.

Q2: Can it be used on both manual tools and automated systems?

A: Yes, it is compatible with handheld grinders as well as robotic finishing systems commonly used in automotive assembly lines.

Q3: Is it suitable for aluminum and stainless steel?

A: Absolutely. The wheel works effectively on aluminum alloys, stainless steel, silicon bronze, and other metals commonly used in laser brazing.

Q4: How long does one wheel last?

A: Service life depends on application conditions, but thanks to the cotton-fiber construction and premium abrasives, it lasts significantly longer than conventional finishing wheels.

Q5: Can you provide product samples before bulk orders?

A: Yes, we can supply samples for testing to ensure the wheel meets your application requirements.

Notice

The safety performance of Nice Top grinding wheel is strictly tested and has clear safety operation instructions. However, it is still essential to install and use it properly and stick to the safety instruction. Each product is labeled with the MOS: Maximum Operating Speed. The actual operating speed can not exceed the maximum operating speed.

Moreover, Please also pay attention to the mechanical protection, wear the mask, safety glass and safety shoe. Pay attention to the ventilation of the workshop.

Due to variations in product models, specifications, and production lead times, prices may differ across different items. To receive an accurate quotation, we sincerely invite you to contact us with detailed product information, such as model number, dimensions, and estimated purchase quantity. Based on the details provided, we will offer a customized price quotation. We are also open to offering reasonable discounts depending on your order volume or specific requirements.

We warmly welcome your inquiries and are committed to working with you to find the most suitable and cost-effective solution.