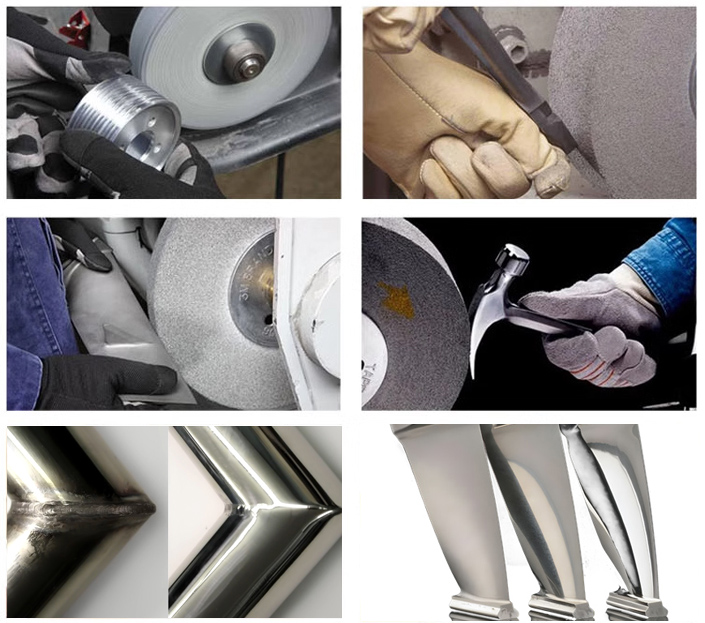

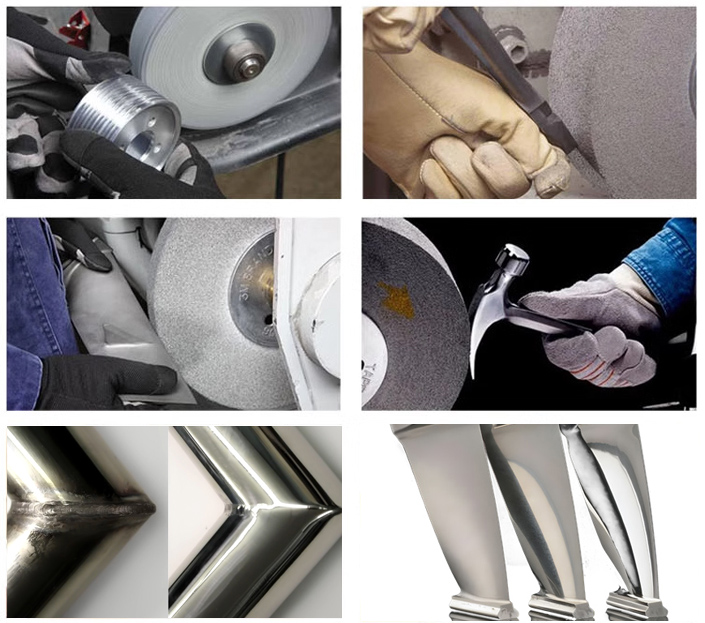

The Deburring convolute wheel is suitable for various of precision polishing and light deburs. It is designed to provide a clean and economical system for removing fine burrs while providing a highly polished finish. Used for fine deburring, polishing and finishing because of their conformability, Convolute Wheels will maintain critcal tolerances while still providing a fine polished finish. LDP can be used as the best quality of light debur wheel. The applications include grinding hydraulic valve core, mold and pressure parts grinding&polishing, aircraft parts polishing, furniture glass oblique edge polishing, etc.

The convolute wheel is an improved version of the LDP wheel, which further improves the grinding force and the efficiency of grinding, blending and drawing.

Product Parameters

| Abrasive Material | Aluminum Oxide, Silicon Carbide |

| Application | Polishing, Deburring, Finishing |

| Brands | Nice Top |

| Overall Diameter | 8inch/203.2mm |

| Thickness | 0.5inch/12.7mm |

| Center Hole Diameter | 3inch/76.2mm |

| Grade | Coarse, Medium, Fine |

| Industries | Aerospace,Auto Manufacturer,Medical Equipment,Metalworking |

| Place of origin | China |

| Customized support | OEM, ODM |

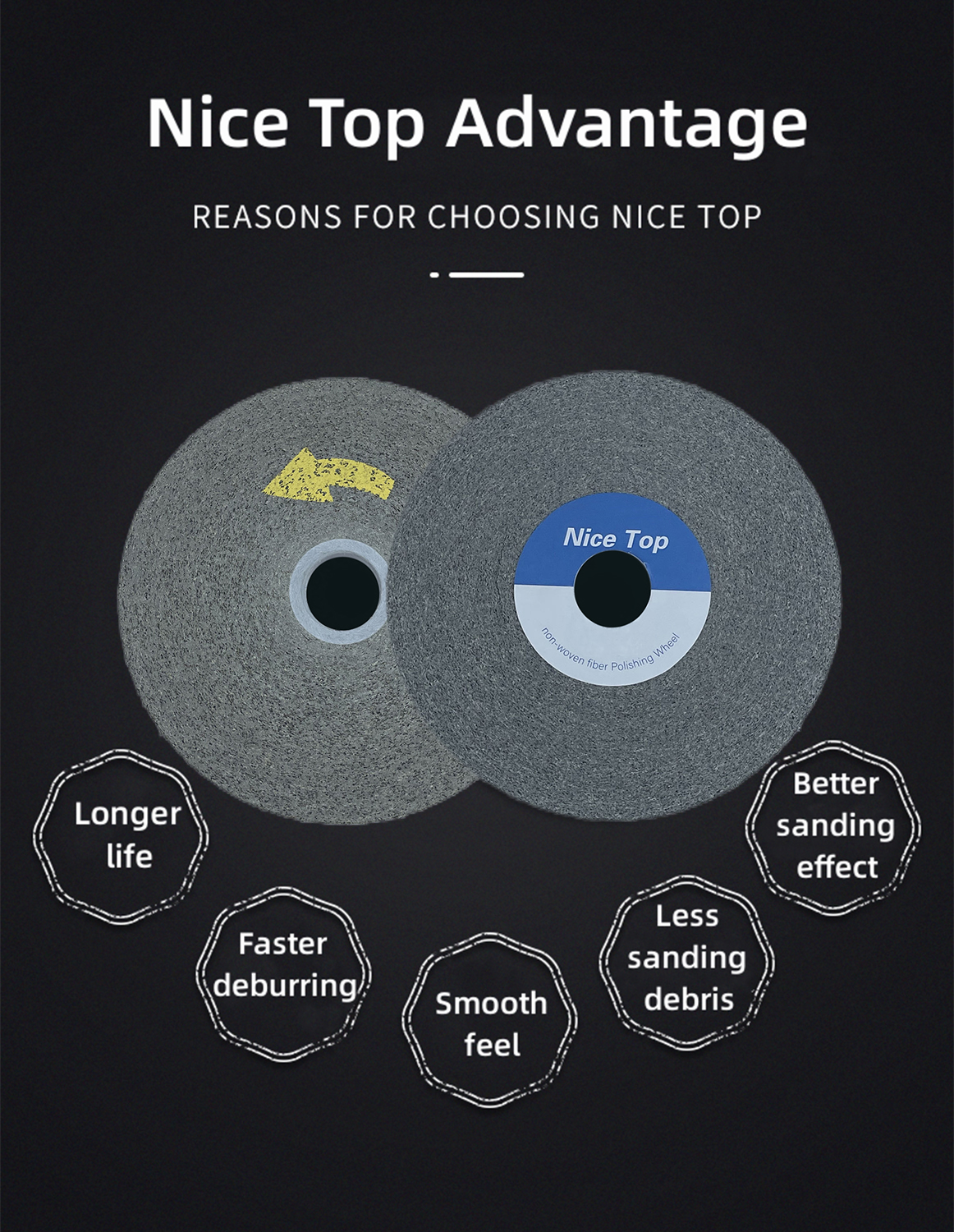

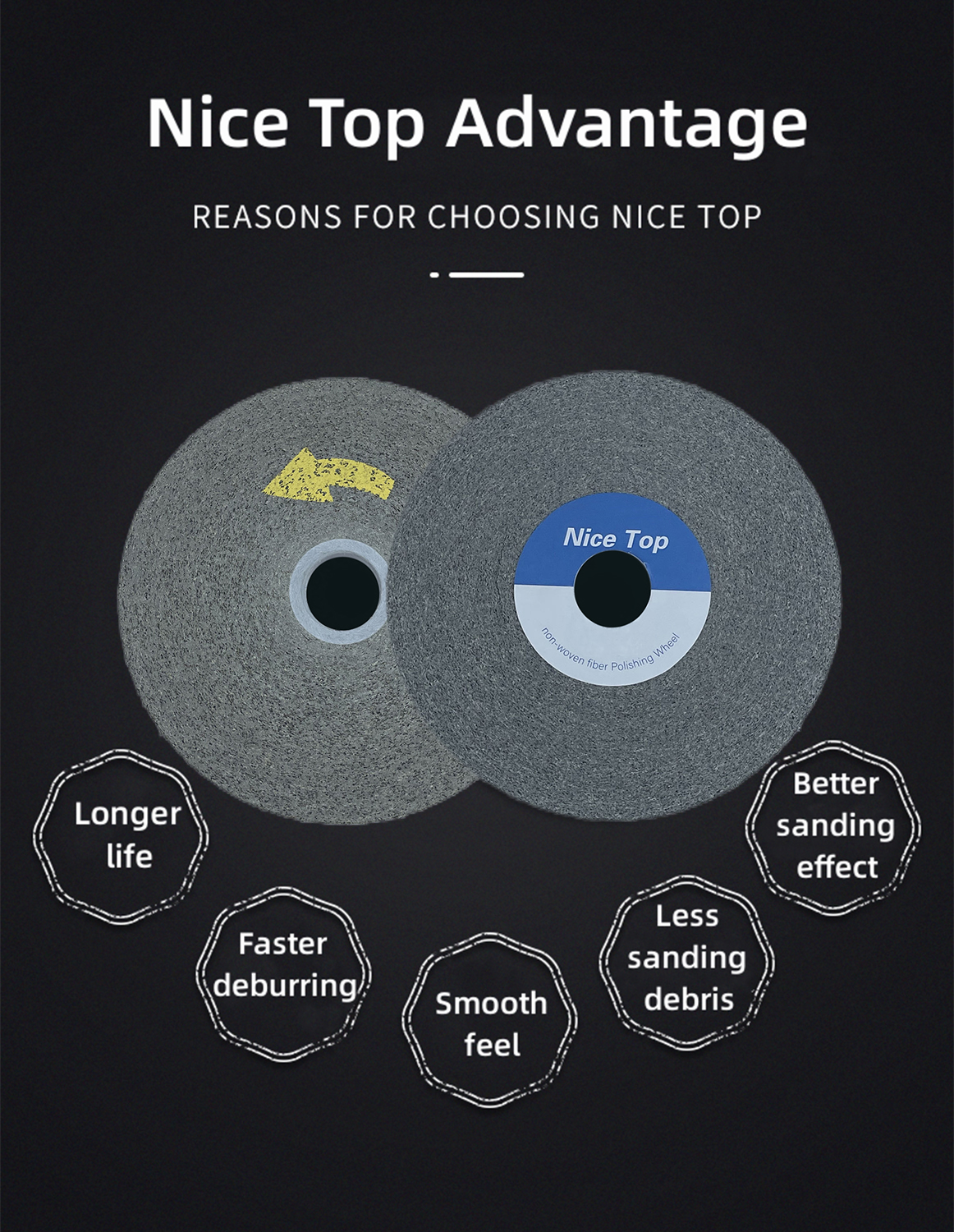

Features

Gentle Grinding

Made from soft, high-quality fiber material, the wheel provides controlled, gentle contact with the metal surface. It efficiently removes minor imperfections while maintaining the integrity of the workpiece, preventing scratches, deformation, or unwanted surface changes. This makes it ideal for applications that require precision and delicate finishing, such as stainless steel, aluminum, or decorative metal components.

Uniform Grinding

The unique fiber structure ensures consistent distribution of grinding force across the entire surface. This design allows the wheel to deliver a smooth, even finish while avoiding over-grinding or localized wear. As a result, it produces a balanced texture that improves both the appearance and dimensional accuracy of the finished part, making it highly effective for precision manufacturing or surface restoration.

Efficient Deburring

Capable of quickly removing burrs, welding slag, and oxide layers, the metal finishing wheel significantly improves surface cleanliness and smoothness. It reduces manual rework time and ensures cleaner edges for subsequent processes such as coating, welding, or assembly. This high-efficiency performance is especially suitable for metal fabrication, automotive, and machinery industries.

Durability

Constructed from premium, wear-resistant fiber materials, the wheel offers excellent longevity and maintains consistent cutting power over extended use. Even under continuous operation, it resists clogging and deformation, ensuring stable grinding efficiency and lower replacement frequency. This results in a longer service life and reduced operational costs for users.

Applications

Metal Processing

The Convolute Wheel efficiently grinds, deburrs, and polishes metal parts, removing burrs and oxidation for improved surface finish and dimensional accuracy. Ideal for stainless steel, aluminum, and carbon steel applications.

Automobile Manufacturing

Used for polishing car bodies, engines, and parts, it refines welds and surfaces, enhancing product quality and appearance. Its wear resistance ensures stable, efficient production.

Ceramic Processing

Provides precise grinding and polishing for ceramics, preventing cracks and improving surface smoothness and gloss—suitable for industrial and decorative applications.

Plastic Processing

Removes surface defects and weld marks from plastic parts without deformation or heat damage, improving texture and appearance for consumer and industrial use.

Summary

The Convolute Wheel outperforms the Norton 1000 Series Long-Life Wheel in durability, grinding efficiency, and stability. It is a cost-effective, high-performance solution for diverse polishing and deburring needs across multiple industries.

Frequently Asked Questions (FAQ)

Q1: why should you buy from us not from other suppliers?

A: Nice Top has strong capability to design and produce world top convolute wheel, unitized wheel,bristle brushes & discs,non woven Polishing wheel,laser braze finishing wheel etc. We give you competitive price and never comprise to quality.

Q2: Can it be used on both manual tools and automated systems?

A: Yes, it is compatible with handheld grinders as well as robotic finishing systems commonly used in automotive assembly lines.

Q3: Is it suitable for aluminum and stainless steel?

A: Absolutely. The wheel works effectively on aluminum alloys, stainless steel, silicon bronze, and other metals commonly used in laser brazing.

Q4: How long does one wheel last?

A: Service life depends on application conditions, but thanks to the cotton-fiber construction and premium abrasives, it lasts significantly longer than conventional finishing wheels.

Q5: Can you provide product samples before bulk orders?

A: Yes, we can supply samples for testing to ensure the wheel meets your application requirements.

Notice

The safety performance of Nice Top grinding wheel is strictly tested and has clear safety operation instructions. However, it is still essential to install and use it properly and stick to the safety instruction. Each product is labeled with the MOS: Maximum Operating Speed. The actual operating speed can not exceed the maximum operating speed.

Moreover, Please also pay attention to the mechanical protection, wear the mask, safety glass and safety shoe. Pay attention to the ventilation of the workshop.

Due to variations in product models, specifications, and production lead times, prices may differ across different items. To receive an accurate quotation, we sincerely invite you to contact us with detailed product information, such as model number, dimensions, and estimated purchase quantity. Based on the details provided, we will offer a customized price quotation. We are also open to offering reasonable discounts depending on your order volume or specific requirements.

We warmly welcome your inquiries and are committed to working with you to find the most suitable and cost-effective solution.